Shanghai (Gasgoo)- Recently, NIO mapped out a decade of work on its chassis technology. From its own vantage point, the company retraced the path from its first production model to today — moving from early reliance on international suppliers to gradually bringing key components and control systems in house, and ultimately taking part in setting industry standards.

From supplier reliance to core in‑house R&D

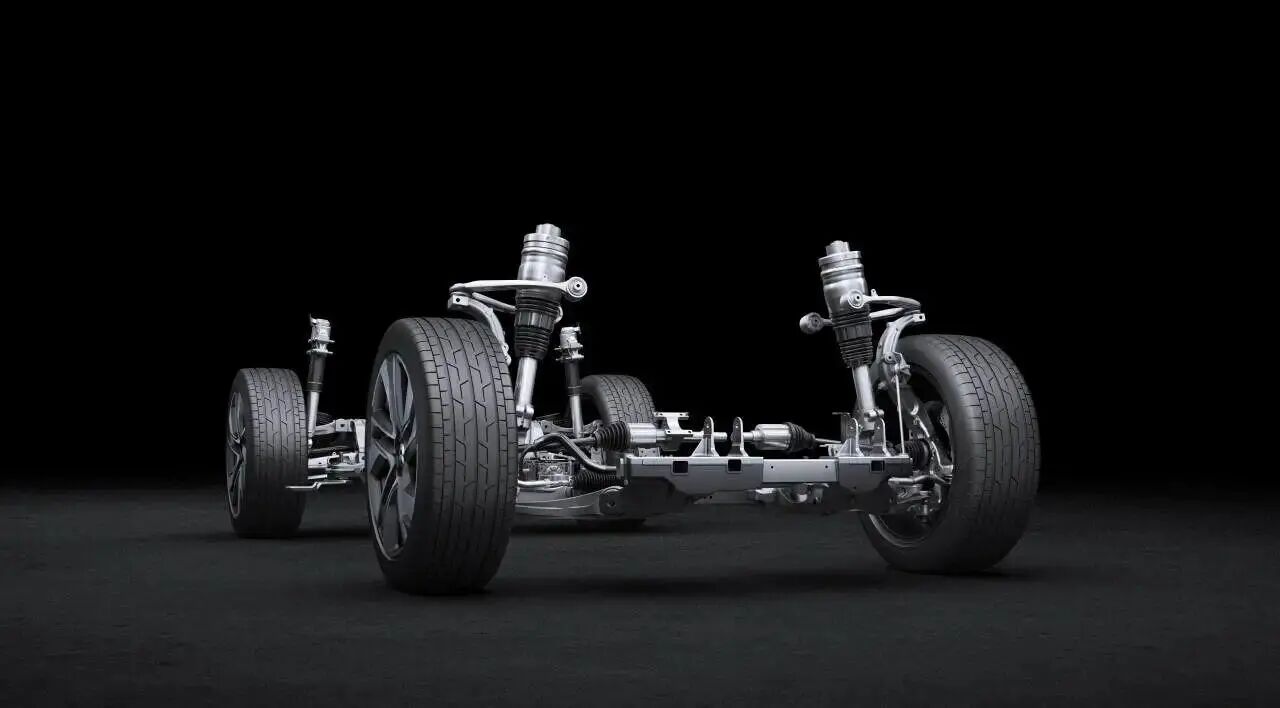

When NIO entered carmaking in 2014, its first volume model, the ES8, opted for high‑spec hardware at the chassis level, including an all‑aluminum structure and air suspension. As a new entrant, NIO encountered caution from top‑tier international suppliers. Most worked on an "off‑the‑shelf" basis, meaning automakers could only pick from established product libraries with no room for customization. The result: hardware sourced from different suppliers carried incompatible underlying control strategies. Individual components performed at a top‑tier level, yet the lack of unified, coordinated systems engineering led to clear inconsistencies in the ES8's dynamic behavior.

Image source: NIO

Fixing the problem took time. By engaging directly with suppliers' senior management, NIO set up joint task forces and spent more than two years refining logic and calibration at the software layer, gradually lifting the experience to mainstream levels. The lesson was clear: under traditional supply models, the chassis' core control logic is a "black box" to OEMs. That leaves companies unable to quickly implement fixes and iterations in response to user feedback — a fundamental barrier to continuous improvement.

So in late 2019 to early 2020, even as the company faced heavy operational pressure, NIO opted to develop a full‑stack Intelligent Chassis Controller (ICC). The goal was to put the system's "brain" — control logic and algorithms — firmly in its own hands, securing the ability to define and continuously optimize product experience.

The challenge went beyond software to the hardware supply chain. At the time, leading international suppliers typically sold hardware bundled with controller algorithms and refused to provide core mechanical parts such as air springs on a standalone basis. NIO turned to supporting domestic suppliers with strong potential but limited series‑production experience. The company went far beyond procurement, offering deep support in validation systems, production process set‑up and even early talent hiring — effectively helping build partners' capabilities. For the domain controller hardware, NIO also adopted a "white‑box" cooperation model with domestic electronics partners: tightly integrated teams, shared IP, co‑development. In 2021, the ET7 equipped with the full‑stack ICC went into production. That marked the point where NIO could directly adjust parameters and deploy algorithms at the central domain controller layer, enabling the chassis system to receive OTA updates for feature upgrades and experience refinement.

Complex engineering rollout and standard‑building

With chassis domain control in hand, NIO planned a more complex, cutting‑edge integration package for its flagship sedan, the ET9. The program aimed to combine fully active hydraulic suspension (FAS), steer‑by‑wire (SbW) and rear‑wheel steering (RWS) — technologies not yet commonplace in the industry. Each is challenging on its own; integrating multiple high‑dynamic, high‑complexity actuators on one platform and making them work in concert is a systems‑engineering hurdle.

FAS development and adaptation proved emblematic. NIO partnered with ClearMotion, a startup with advanced concepts but limited mass‑production experience. Early tests on modified vehicles showed that systems calibrated for European roads underperformed on China's typically complex paved surfaces — sometimes worse than conventional suspension. NIO's engineering team brought its self‑developed control logic and matched components to the partner's site for months of joint tuning, reworking the hydraulic system's matching logic so the setup could meet China's specific road challenges. The team also tackled protective shutdowns triggered by microsecond‑scale current spikes, which required a fresh, bottom‑up design of the 48V power system's output and protection specifications.

The SbW implementation reflected a different safety philosophy. On the ET9, NIO adopted an all‑electronic solution with no mechanical backup. To ensure absolute reliability, its safety architecture drew on aerospace thinking and built three tiers of redundancy: first, dual‑channel backups across sensing, compute, communications, power and actuation; second, primary and secondary systems sourced from different suppliers with divergent software logic to prevent common‑cause failures; and third, a vehicle‑level fallback, where coordinated braking and rear‑wheel steering keep the car controllable in extreme situations. To address SbW's inherent "hand faster than car" response lag, NIO and partner ZF boosted motor power and optimized control algorithms.

Image source: NIO

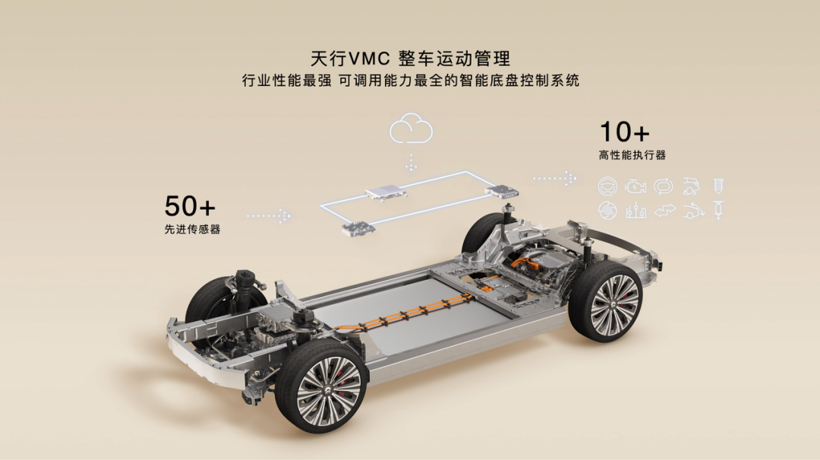

NIO also developed a chassis compute platform (VMC). Acting as the hub for vehicle‑level motion coordination, its core value lies in cross‑system optimal decision‑making and predictive control — allowing, for instance, rapid assessment and orchestration of system‑wide interventions during transient extremes such as a high‑speed blowout to keep the vehicle stable.

Bringing these advanced technologies to production initially ran up against gaps in domestic standards. With no national‑level evaluation method for SbW systems at the time, NIO pursued a special path — a "new‑technology review" — submitting to an MIIT‑organized expert committee a comprehensive validation and safety dossier covering 10 categories and 41 rigorous tests. After multiple rounds of review, the ET9 received product bulletin approval in November 2024.

NIO's chassis journey — from supplier dependence to core in‑house development and then to tackling high‑complexity system integration — mirrors a broader shift in smart EVs: the chassis is evolving from a purely mechanical performance carrier into an intelligent platform that fuses perception, decision‑making and execution.

Today, intelligence has entered deep water. The core of the smart chassis race is shifting from standalone hardware metrics to system‑level, fine‑grained mastery of vehicle motion control. Striking the right balance among technological foresight, engineering reliability, cost and user experience will remain a long‑running test for the industry.