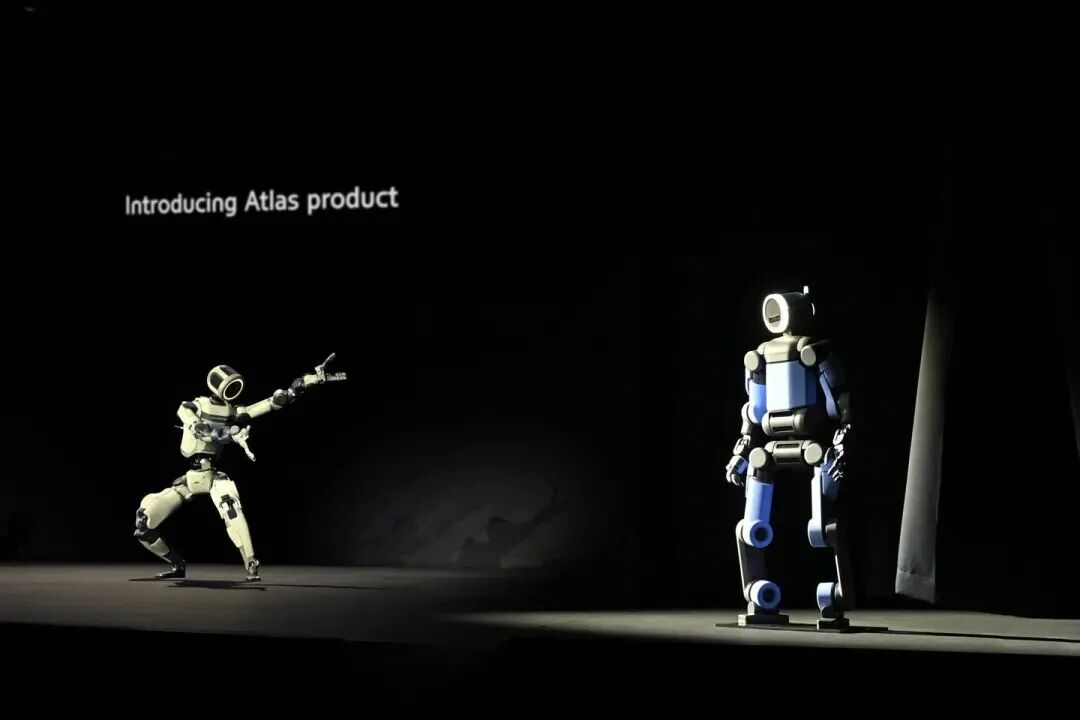

Boston Dynamics' hydraulic Atlas, once a serial backflipper that stunned the world, ceded the CES 2026 spotlight to a plain-looking, sure-footed all-electric Atlas — not just a product iteration, but a pragmatic pledge to the industrial world.

On January 6 local time, at CES in Las Vegas, Boston Dynamics officially unveiled the next-generation all-electric Atlas humanoid robot. It stands about 1.9 meters tall, weighs 90 kilograms, carries 56 degrees of freedom, and can handle loads of roughly 50 kilograms — each spec aimed squarely at a practical goal: efficient, reliable industrial labor.

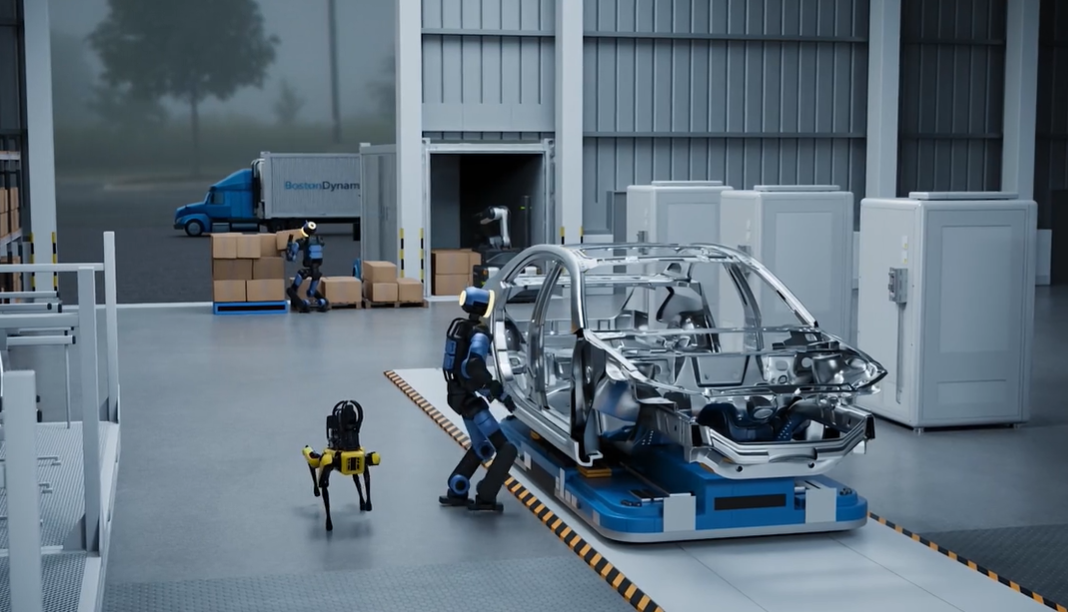

In the demo video played at the show, the new Atlas skipped the usual stunts and walked into a workshop, methodically tackling battery swaps, parts sorting and material handling. No soaring soundtrack, no breath-stopping flips — just the steady cadence of a line worker.

This muted debut can be read as Boston Dynamics’ loud declaration: the era of conquering the internet with showmanship is over; the era of winning over factories with real work has begun.

Image credit: Hyundai Motor

New Atlas, born for 'real work'.

As the core of this launch, every design choice on the new Atlas is stamped with commercial intent: built for real production.

It leaves behind the lab's pursuit of extreme human-likeness, and instead follows tougher industrial rules: maximize reliability, serviceability and task efficiency — not simply "look human."

At the event, Ya Durban, who leads product strategy for humanoid applications at Boston Dynamics, put the shift plainly: "Our vision is to build a general-purpose humanoid — one that can go anywhere, understand its surroundings, and operate any object."

Industrial settings, for now, are Boston Dynamics’ focus. "We're building a tool that can be deployed directly into your existing facilities — not just to do one task, but flexible enough to evolve as your business changes," Ya Durban said.

To that end, Atlas' design abandons the fixation on mimicking humans and instead chases an engineering optimum: efficiency beyond human.

Image credit: Boston Dynamics

Consider Atlas' nearly 1.9-meter height: it can lift 110 pounds (about 50 kilograms), and its arm reach height is up to 7.5 feet (about 2.3 meters). That fits the station heights, tool benches and aisle widths in existing auto plants — without reworking the line.

For more dexterous manipulation, Atlas uses four-finger hands roughly the size of a human palm, with tactile sensing embedded in the hand.

To address stability issues that come with a taller frame, Atlas adopts flat feet — trading some human-likeness for more reliable mobility and lower operational risk in industrial environments.

Beyond that, compared with the taut, sport-focused feel of the hydraulic Atlas, the new Atlas' limbs and joints are tuned to the realities of industrial work.

According to Zach Jackowski, vice president and general manager of humanoids at Boston Dynamics, Atlas has 56 degrees-of-freedom joints, most of which can rotate 360°. That lets Atlas move more efficiently than a human, especially in tight, time-critical manufacturing spaces — because both its head and waist rotate 360°, it doesn't need to turn its whole body to operate, which notably improves flow and efficiency.

That "tool-first" thinking even extends to the human–machine interface. Atlas' head carries a 360-degree panoramic camera, which senses the entire environment without turning, boosting safety. "We want people working with Atlas to know Atlas is a helpful robot, not a person," Zach said.

Commercial success also hinges on maximizing uptime and minimizing maintenance costs. Atlas adopts a modular architecture and rapid-service design so on-site maintenance feels like swapping parts on industrial equipment.

Image credit: Boston Dynamics

To that end, the new Atlas carries a quick-swap dual-battery system. A single charge runs about 4 hours; when power is low, it autonomously navigates to a charging station, swaps its battery and returns to work immediately — enabling 24/7 operation that matches the continuous rhythm of industrial production. In China, UBTECH's Walker S2 uses a similar swap scheme.

Atlas' joints and actuators are built as standard modules for rapid removal and replacement. In the launch video, Boston Dynamics emphasized swap-ability and recomposability to dramatically cut maintenance complexity and downtime — creating a work loop that’s nearly continuous.

To better meet high-intensity operations, particularly in extreme environments, Atlas also sets industrial-grade baselines for durability: it is water-resistant and can operate fully from about -20°C to 40°C. In practice, that means sustained work in warehouses without air conditioning, hot workshops or cold loading zones.

Ultimately, the ease of large-scale commercial deployment comes from software.

Through Boston Dynamics’ Orbit platform, Atlas can rapidly replicate capabilities: any skill learned by one Atlas can be synced to the rest. Most tasks, we’re told, can be trained within a day.

That not only speeds deployment, it means Atlas’ value grows with software iterations and an expanding skill library — becoming a productivity asset that keeps evolving.

Strategic metamorphosis: from a tech island to an industrial continent

The new Atlas' product philosophy marks Boston Dynamics' most profound strategic pivot in more than three decades. The company's story reads like a chronicle of tech idealism colliding with commercial reality — then slowly fusing.

Founded in 1992, Boston Dynamics spent its first twenty years as a "dream lab" solving transport in extreme conditions for the U.S. military.

From BigDog to LS3, those early quadrupeds demonstrated striking terrain adaptation and load movement — solving foundational challenges of dynamic motion in the complex physical world. Yet high costs, heavy noise and defense ties kept them far from mainstream markets.

In 2013, Google acquired Boston Dynamics, giving commercialization its first lift.

During that period, the hydraulic Atlas went viral — fluid backflips, precise triple hops and other high-difficulty moves drew tens of millions of views, vaulting the company to internet fame and briefly raising hopes it would accelerate productization.

Image credit: Boston Dynamics

Even so, that five-year "marriage" ended with an acquisition by SoftBank Group. Beyond big-tech strategy shifts, a deeper tension persisted: Boston Dynamics still lacked a clear path to commercialization. Robots such as the hydraulic Atlas and SpotMini, while breathtaking in videos, remained "tech demos" — thin on practical function definitions for specific industries.

Take the first Atlas' hydraulic system. It delivered unmatched burst power and dynamic performance, but technical complexity, high cost, heavy energy use and intricate upkeep baked in — all at odds with scalable, low-cost, high-reliability commercial requirements.

It wasn’t until Hyundai Motor Group's acquisition in 2021 that Boston Dynamics reached a decisive inflection point.

Hyundai's three critical advantages are steadily pulling Boston Dynamics off its pedestal and onto solid industrial ground:

First, Hyundai offers a key "launch customer" and a real-world proving ground. Its global auto plants provide the most brutal and authentic test arena — and a priceless flywheel of physical-world data.

Second, as a world-class manufacturing giant, Hyundai brings deep supply-chain management, cost discipline and a sharp understanding of enterprise customers — directly plugging gaps typical of pure tech firms.

Third, Hyundai can produce and optimize the actuators, sensors and structural parts robots need at industrial scale — a precondition for turning lab prototypes into products priced within reach.

Image credit: Boston Dynamics

Before this, Boston Dynamics and Hyundai had already scaled deployments of the quadruped Spot and the wheeled mobile robot Stretch. At the launch, Ya Durban disclosed that production of the new Atlas has begun at headquarters — and all of its 2026 output has been allocated to Hyundai Motor.

Boston Dynamics has already deployed Atlas in Hyundai's U.S. factories for autonomous material handling, collecting data and experience to bring back. Next, it plans more pilots across Hyundai Motor Group, and to add more customers in 2027.

From 2028, Atlas will be introduced into processes where safety and quality benefits matter, such as parts sorting. By 2030, Atlas' use will extend to component assembly, and over time it will take on repetitive motions, heavy loads and other complex tasks. Ultimately, Hyundai aims to roll it out across its production base.

To support this, Boston Dynamics and Hyundai are building a Robotics Metafactory Application Center (RMAC), designed to compile a complete dataset for training humanoids in manufacturing skills — essentially a "data factory" for robots.

In parallel, Hyundai is building a scalable robot production system: Hyundai and Kia provide manufacturing infrastructure, process control and large-scale production data; Hyundai Mobis is working closely with Boston Dynamics to develop high-performance actuators and will enter the global robotics components market; Hyundai Glovis oversees logistics and supply-chain optimization to ensure efficient delivery.

Hyundai will also provide OTA software updates, hardware maintenance backed by remote monitoring, repair and upkeep services, plus one-stop service and expansion plans — turning robot tech from one-off sales into flexible, recurring service.

Image credit: Hyundai Motor

In other words, an Atlas — from design, through core parts production and assembly, to final deployment — will be completed within Hyundai's system, tightly controlling cost, quality and delivery.

Ultimately, Boston Dynamics and Hyundai aim to build a capacity of 30,000 robots per year by 2028.

Beyond Hyundai's value network, Boston Dynamics has deep partnerships with Google DeepMind and NVIDIA, forming a closed-loop ecosystem of "body (in-house) + AI brain (DeepMind) + compute (NVIDIA) + application scenarios (Hyundai)."

Through that layered cooperation, Boston Dynamics has begun to break the old "tech self-loop" and complete a first metamorphosis — from a roaming tech star to a company rooted on the industrial continent.

Industry turning point: from showmanship to commercial ramp

Boston Dynamics' turn from "lab star" to "cyber shop-floor worker" isn't unique; it signals a broader shift: humanoid robotics is moving past the demo phase and into a mass-production race centered on commercial value.

Multiple forces are driving the inflection.

First, technology paths are converging. Not long ago, hydraulics versus electric drives — and extreme bionics versus practicality-first — dominated the debate.

Image credit: Tesla website

Today, hard economics and cost discipline are rendering those arguments moot. From Tesla's electric-only Optimus, to Boston Dynamics' shift from hydraulics to electric, to domestic leaders such as Zhiyuan, Unitree and UBTECH, electric drives — with lower maintenance, higher energy efficiency and better scalability — have become the mainstream direction.

The picture echoes the auto industry's early transition from combustion to electric: once the base tech path converges, the competitive focus jumps from "how to drive" to "how to drive smarter and more efficiently."

On form factor, "function first" is also gaining ground. Overly human-like, complex joint designs are giving way to stability and reliability around core tasks. Most companies need a precise material handler for the line — not an acrobat doing backflips on stage.

Discussion of the new Atlas on social media mirrors that shift. Many comments cut to the point: "Looking human isn't important; efficiency and practicality are," "No need to force a human form — choose what works best," "Robots should do the work and replace human labor — why insist they look like us?"

Dissent exists, but the pragmatic tone itself signals maturation. As tech fantasy meets industrial reality, the market will pick winners by a single measure: can they solve real problems?

Second, competition has moved up a level. Early humanoid races focused on single-point breakthroughs — steadier gaits, flashier moves. Today it's a full-stack battle across technology depth, ecosystem breadth and sustainable business models. Three archetypes are emerging:

Tesla's model: port AI capability, supply chain and manufacturing expertise from the car business directly into robots — cutting costs and lifting efficiency to build a general-purpose robot most can afford;

Boston Dynamics–Hyundai: through deep ecosystem ties, bind technology, manufacturing and scenarios to deliver high reliability and task autonomy in complex, unstructured environments — with reliability and depth at the core;

China's model: leverage intimate market understanding, agile engineering and strong supply chains to focus on niches such as smart manufacturing, commercial services and home companionship — rapidly shipping deliverable, usable solutions. The core is speed and applicability.

Image credit: UBTECH

This race is no longer a uniform 100-meter dash; it's a marathon of divergent strategies and paths. Chinese players are showing notable acceleration, with UBTECH, Unitree and GALBOT among those racking up commercial orders — pointing to a "China push" driven by supply chains and real-world applications.

Third, macro tailwinds are converging as never before.

On policy, many countries treat AI and robotics as strategic industries; economically, shifting labor structures and manufacturing upgrades create rigid demand; socially, acceptance of human–robot collaboration is rising.

These forces aren't trickles but an irreversible flood — carrying humanoids past the shallows of hype and stagecraft into the deep water and main channel of scale and commerce.

Conclusion

Boston Dynamics' strategic rebirth redefines the core value of robots: not to mimic human motion, but to extend human capability; not to perform under spotlights, but to create value on the production line.

This competition, spanning technology and industry and connecting present to future, has no final act — only continual iteration and evolution. The new Atlas, for its part, sets new rules: pragmatism first, value on top.