Here are this week's major developments in embodied AI and assisted driving:

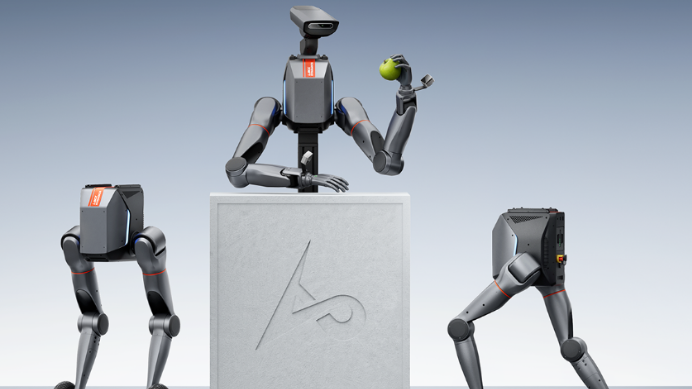

Humanoid Robots Head to Space! ENGINEAI Robotics Partners with Interstellor

In late January, ENGINEAI Robotics and Interstellor have formed a deep strategic partnership to launch a Humanoid Robot Astronaut Exploration Program. The initiative will use ENGINEAI's self-developed embodied general intelligent agent, the PM01, as a core platform to conduct task verification for space environments.

This marks the first application of a humanoid robot system in a space exploration scenario within China, representing a significant intersection between embodied AI technology and aerospace engineering.

Image Source: ENGINEAI Robotics

As ENGINEAI's core robotic platform, the PM01 is equipped with a high-precision environmental perception system using multi-sensor fusion, a millisecond-level real-time motion control module, and a decision-making framework based on proprietary algorithms. It boasts the ability to perceive, judge, and execute continuous tasks in dynamic environments. The robot has completed multiple rounds of high-load, highly complex technical verification on the ground. This attempt at space application means its technology stack will face direct tests from harsh conditions like vacuum, microgravity, extreme temperatures, and radiation.

Space environments demand far higher reliability and autonomy than ground-based scenarios. The partnership leverages complementary technical strengths: ENGINEAI brings expertise in robotic motion control, complex environment adaptation, and embodied AI algorithms, while Interstellor contributes aerospace engineering experience and the ability to adapt to space mission scenarios. The preliminary phase has already involved multiple rounds of joint simulation and risk assessment.

In space missions, robots can undertake tasks such as extravehicular inspections, equipment maintenance, and hazardous environment detection, easing the workload and risk for astronauts. At the same time, the extreme space environment serves as a high-level testing ground for the reliability and robustness of embodied AI systems, with feedback expected to drive iterative upgrades in industrial applications on the ground. In the long run, the "human-machine collaboration" model will become a key pillar in building a sustainable space operations system.

Moving forward, technical teams from both sides will focus on adapting the PM01 for the space environment, optimizing on-orbit task algorithms, and enhancing system reliability, gradually advancing the project from ground verification to space experimentation. This collaboration is viewed as a substantive step in cross-sector collaboration between China's intelligent robotics and aerospace sectors.

Xiao Zhi Comment: This marks a substantive step in the cross-sector collaboration between embodied AI and aerospace engineering.

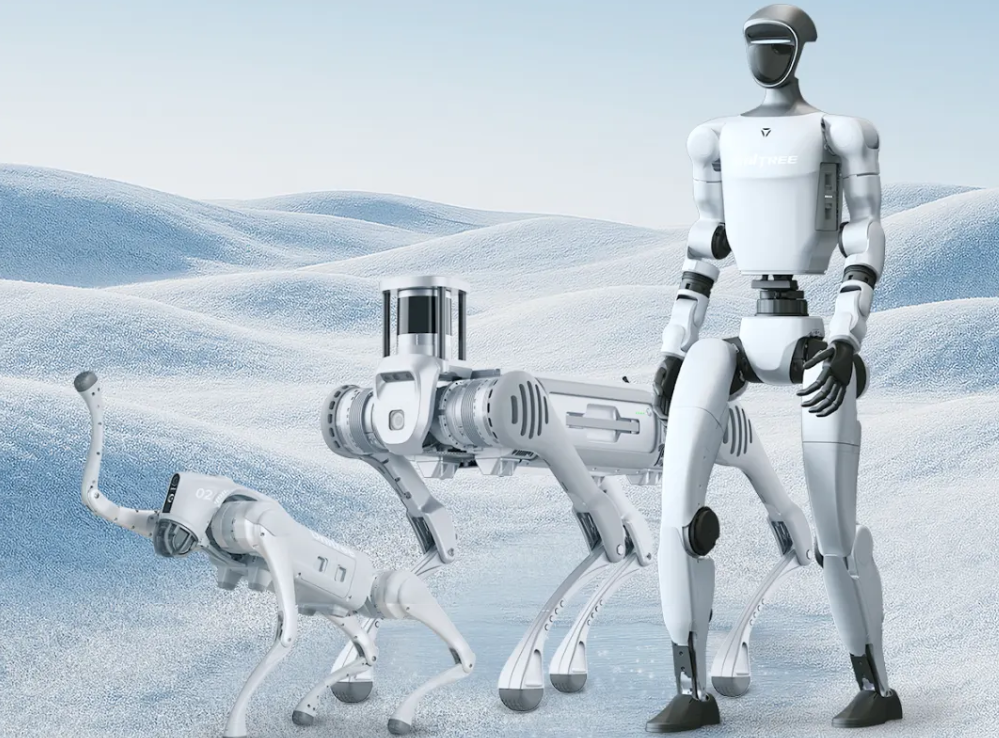

Unitree Announces Appearance at 2026 CCTV Spring Festival Gala

Following MagicLab and Galbot, Unitree officially announced on the evening of January 26 that it has become the "Robot Partner for CMG's 2026 Spring Festival Gala," marking the company's third collaboration with the CCTV gala.

Since the debut of the robotic ox "Benben" at the 2021 Ox Year Gala, to the phenomenal breakout of the humanoid robot show "YangBOT" directed by Zhang Yimou in 2025, Unitree has added highlights to the gala with technological elements for consecutive years. For the 2026 gala, Unitree stated it will "once again join hands with CMG to present a Lunar New Year's Eve feast leading global technological progress."

Image Source: Unitree

Beyond the public stage, Unitree continued to expand robot application scenarios in 2025: it hosted the world's first humanoid robot fighting competition and won four gold medals at the inaugural Global Humanoid Robot Sports Games, becoming the enterprise with the most golds and total medals. Meanwhile, its robots also appeared on theater and concert stages for the first time, allowing the public to experience the diverse appeal of robots up close. In the industrial sector, Unitree's quadruped and humanoid robots have achieved large-scale deployment in relevant scenarios.

According to third-party public data, Unitree has ranked first globally in shipments of both quadruped and humanoid robots in recent years, achieving mass delivery. As research results and industry application scenarios expand rapidly, its robotic products are entering public life with increasing frequency.

Xiao Zhi Comment: Leveraging the Spring Festival Gala stage, Unitree continues to lead the integration of robotic technology into mass culture and life, while maintaining its lead in global shipments and accelerating the deployment of diversified scenarios.

Musk: Tesla Needs to Build Its Own Chip Factory

According to Bloomberg's report, Tesla CEO Elon Musk recently stated the company needs to build and operate a "TeraFab" for semiconductor production. This massive project, costing tens of billions of dollars, marks Tesla's latest expansion beyond its core electric vehicle business.

Image Source: Musk's X account

"To eliminate supply bottlenecks that could arise in the next three to four years, we must build a Tesla TeraFab," Musk said on Tesla's earnings call on January 28. "This will be a super-large wafer fab that independently produces logic chips, memory chips, and completes chip packaging processes."

As the world's most valuable automaker, Tesla is betting its future on artificial intelligence, autonomous driving, and robotics. These projects require massive amounts of chips, with current suppliers including Samsung Electronics and TSMC.

Musk noted that existing suppliers, including TSMC, Samsung, and Micron Technology, cannot meet Tesla's chip demand volume.

"This is crucial for us to hedge against geopolitical risks," Musk said. "I think some people underestimate some of these geopolitical risks, and these risks will become a key influencing factor in the coming years."

The global supply of high-end chips relies heavily on TSMC and its local production capacity in Taiwan.

In recent weeks, the world's richest man has signaled that Tesla might produce chips independently to solve supply constraints. In the fierce race for artificial intelligence, he views insufficient chip supply as a core bottleneck.

"If we don't build a wafer fab, we will inevitably hit a chip supply wall," Musk said in a recent interview. "We have only two choices: either hit the chip supply wall, or build our own wafer fab."

Last November, Musk also revealed to Tesla shareholders that the company might need to build a "TeraFab," stating: "I don't see any other path to get the volume of chips we need."

The profitability of the chip manufacturing industry is severe. Building a top-tier wafer fab requires hundreds of billions of dollars in fixed costs and takes significant time to complete construction, start production, and achieve full operation.

The project also requires purchasing complex equipment from multiple suppliers, especially from Europe's ASML. ASML dominates the market for key equipment in wafer manufacturing.

Despite the massive challenges, building a proprietary chip plant aligns with Musk's consistent vertical integration strategy. Bringing core component production in-house allows his companies to operate far more efficiently than peers relying on external supply chains. Tesla, SpaceX, AI company xAI, brain-computer interface company Neuralink, and tunneling firm The Boring Company are seeing their businesses increasingly converge.

It is not yet clear where in the US the wafer fab will be located or the specific construction timeline.

Tesla expects to invest over $20 billion in capital expenditure for its existing factories this year. The funding sources for infrastructure projects like the solar cell manufacturing factory and the chip wafer fab remain undetermined.

Tesla CFO Vaibhav Taneja stated: "We hold over $44 billion in cash and investment assets on our books. So we will use internal funds, but there are other financing channels." He added: "As long as we have stable cash flow, we can apply for financing from banks."

Vaibhav Taneja also noted: "We have already discussed this with several banks. Further study is needed on the financing plan, such as whether to increase debt financing or use other methods."

Musk stated that Tesla will release more significant announcements regarding TeraFab in the future.

Xiao Zhi Comment: Musk announces Tesla will build a super-large wafer fab, an aggressive move aligning with its vertical integration strategy to address chip supply and geopolitical risks.

Annual Capacity of 5,000 Sets: Beijing-Tianjin-Hebei Gets First Humanoid Robot Pilot Platform

On January 29, a humanoid robot pilot verification platform jointly built by LY iTECH and the Beijing Humanoid Robot Innovation Center was officially launched.

As the first humanoid robot pilot platform in the Beijing-Tianjin-Hebei region, it aims to solve the common industry pain point of "easy R&D, hard mass production," providing a standardized and intelligent carrier for the rapid conversion of technological achievements. Currently, the platform is equipped with 500 sets of trial production and testing equipment, with an annual capacity of 5,000 sets of embodied intelligent robots.

It is reported that LY iTECH is the platform's sole intelligent manufacturing enterprise partner and exclusive operator of the flexible production line, deeply involved in the entire process from construction to operation. This includes providing automated testing equipment, MES and WMS intelligent management systems, and leading the overall construction of the flexible production line.

Furthermore, centering on the core goal of "building an industry benchmark pilot base and exploring a new path for flexible mass production," LY iTECH has formulated four operational plans: establishing a professional operations team, deepening flexible production capabilities, creating a technology transfer accelerator, and building an industrial synergy ecosystem.

Image Source: LY iTECH

LY iTECH is committed to providing global robot clients with one-stop solutions ranging from process processing to core components and OEM/ODM complete machines, aiming to become a global TOP3 manufacturer of embodied intelligent hardware.

Currently, LY iTECH's robotics business has achieved a full-chain layout from core components to complete machine manufacturing, with cooperative clients covering many of the world's leading robotics enterprises. As of November 2025, LY iTECH has completed hardware and assembly services for over 5,000 sets of humanoid (embodied) robots, covering complete machines/dexterous hand assembly, joint modules, and high-precision parts like heads, waists, brains, arms, legs, and dexterous hands, as well as key modules like charging solutions, heat dissipation solutions, and soft textile skins.

LY iTECH previously revealed that the pilot base will gradually be upgraded into a humanoid robot super factory with an annual output of 500,000 units, continuously consolidating its advantage in mass delivery.

Xiao Zhi Comment: The launch of the region's first robot pilot platform focuses on flexible mass production to solve the "easy R&D, hard mass production" bottleneck, aiming for the goal of becoming a global TOP3 embodied intelligent hardware manufacturer.

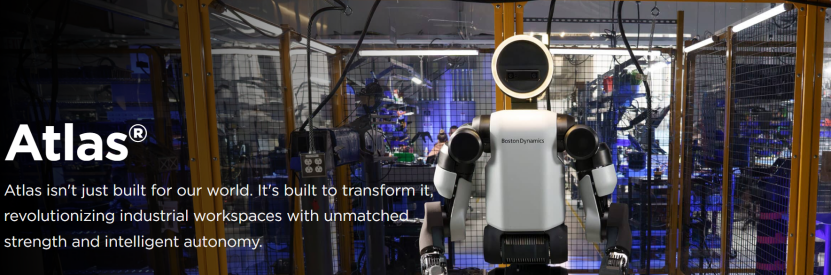

Hyundai Motor's South Korean Union Clashes with Humanoid Robot Plan

According to Reuters' repoprt,on January 22, Hyundai Motor's labor union in South Korea warned the company not to deploy humanoid robots without union approval, stating the move would bring an "employment shock."

Image Source: Boston Dynamics

In an internal letter reviewed by Reuters, the union stated that Hyundai Motor plans to deploy humanoid robots starting in 2028, which has driven its stock price to record highs but is not good news for workers. The union said: "Please remember, without a labor-management agreement, no robots using new technology are allowed to enter the workplace."

Earlier this month, Hyundai Motor Group unveiled the mass production version of the Atlas humanoid robot developed by its subsidiary Boston Dynamics at CES in Las Vegas.

Hyundai Motor Group stated its goal is to build a factory with an annual capacity of 30,000 robots by 2028 and plans to deploy humanoid robots at its plant in Georgia, USA, starting in 2028, with the ultimate goal of expanding applications to all production bases. The union accused Hyundai Motor Group of trying to reduce labor and increase profits by deploying robots.

Hyundai Motor did not immediately comment on the report.

The union also harshly criticized Hyundai Motor's move to shift capacity to the US, stating that its new plant in Georgia, USA, has already caused a substantial impact on domestic production in South Korea and directly threatens employment stability at its two factories in South Korea.

Last year, Hyundai Motor stated that to cope with US tariffs, its Georgia plant's annual capacity will reach 500,000 vehicles by 2028.

Xiao Zhi Comment: Hyundai's union strongly resists the humanoid robot deployment plan, fearing automation will replace human labor, highlighting the labor-management conflict and employment shock amidst the wave of technological innovation.