At the recently concluded 7th New Automotive Supply Chain Conference, the discussions among OEMs and leading suppliers gravitated toward three themes: resilience, sustainability, and the emerging logic of localization.

Topics such as technological innovation and cost reduction received far less attention—not because they are unimportant, but because they have already become the default setting of China's automotive supply chain, happening every day at high frequency.

In this episode of Tina's Talk, we turn our focus to the great divergence of global supply chains. From localization, to globalization, and now to geo-localization, we explore how geopolitical realignments are rewriting the architecture of the global automotive supply chain.

Ⅰ. From Technological Competition to Geopolitical Struggle

Over the past thirty years, we have been accustomed to explaining the competition in the automotive industry through "technology and market." However, the pandemic, geopolitical conflicts, and trade barriers have changed everything. Today, automobiles are no longer just a symbol of industrial competition; they are entangled in a deeper global geopolitical and industrial security struggle.

Energy security, critical minerals, key components, data compliance, and supply chain resilience—these are becoming new variables influencing the industry's direction. The global automotive supply chain is undergoing a fundamental shift from a focus on "efficiency" to an emphasis on "resilience."

For every country and every company, ensuring autonomous and controllable supply chain security is no longer an "optional" issue but a mandatory "survival course."

Ⅱ. The Russia-Ukraine Conflict: Breakdowns in Energy and Supply Chains

In 2022, the Russia-Ukraine conflict erupted, and Europe faced an energy crisis. Natural gas supplies drastically decreased, and electricity, raw materials, logistics, and labor costs skyrocketed, forcing automotive factories to scale back or even halt production.

This crisis presented European industries with a new challenge: can the high efficiency of globalization withstand the high risks of geopolitical conflict? Soon, several companies took action. BMW and CATL jointly built a battery factory in Hungary, Volkswagen signed a long-term supply agreement with Argentine lithium mines, Continental built a connected vehicle products factory in Romania, and Stellantis proposed a "near-shoring" strategy.

Photo source: CATL

Europe's industrial logic is being forced to be rewritten—from reliance on single suppliers to a "diversification + localization" procurement model. A more profound change is that more and more European companies are now incorporating "supply chain stress testing" into their annual strategies, extending the inventory cycle for key minerals, and promoting battery recycling and solid-state battery research, shifting from a "cost-driven" approach to a "resilience-driven" one.

This conflict serves as a stark reminder to everyone—without energy and supply chain security, there is no national or industrial security.

Ⅲ. US-China Tensions: The Formation of Dual Supply Chains

While Europe faces an energy crisis, the geopolitical struggle between China and the US is reshaping the global supply chain landscape through technology and regulations.

In 2022, the US Inflation Reduction Act (IRA) was introduced, with new electric vehicle tax credit requirements: vehicles must be assembled in North America to qualify for subsidies. At the same time, localization thresholds were set for key minerals and battery components, with annual increases. If battery components are manufactured or assembled by "foreign entities of concern" (FEOCs), or if key minerals are mined, processed, or recycled by FEOCs after 2025, the vehicle will not be eligible for the maximum $7,500 tax credit. As a result, some Chinese battery and mineral companies are effectively excluded from the subsidy system.

Meanwhile, the United States has continued to tighten export controls on advanced chips and semiconductor equipment, restricting China's access to high-performance computing for autonomous driving and AI. NVIDIA rolled out downgraded "China-only" versions such as the A800 and H800 to meet earlier control thresholds, but as the rules were further tightened, even these reduced-spec models have come under stricter limitations.

On the battery side, Ford's LFP project with CATL in Michigan adopts a structure designed to navigate U.S. political sensitivities and comply with the IRA as much as possible: Ford owns 100% of the plant, builds and operates the facility on its own, and merely licenses CATL's technology in return for royalty payments.

Photo source: Ford Motor

Two recent news stories have sent new shockwaves through the auto industry. Reuters reported that GM has instructed thousands of suppliers to phase out Chinese components and raw materials by 2027. The Wall Street Journal, meanwhile, reported that Tesla is asking suppliers to avoid using "Made in China" parts when supplying its U.S. factories. These developments have reignited discussions around the emergence of dual supply chains.

The result is that the global automotive industry supply chain is being pushed towards a new structure of "dual-track + bloc-based" supply chains.

First, the Two-track Supply Chains:

One track serves the Chinese market—relying on domestic partners such as CATL, BYD, and Horizon Robotics, forming a complete ecosystem for new energy and intelligent vehicles.

The other track serves North America and Europe—primarily relying on Japanese, Korean, and Western supply systems to meet IRA, FEOC, and EU localization regulations.

Secondly, Bloc-ification of Supply Chains:

Global supply chains are no longer determined by efficiency optimization, but are being re-divided based on geopolitical blocs:

1) "US—Europe—Japan-Korea" forms a bloc with policy and supply chain coordination.

2) "China—ASEAN—Middle East—Latin America" gradually forms another bloc centered around industrial capabilities.

3) Emerging economies will strategically balance and choose between these two blocs.

At the same time, the logic of globalization is undergoing a fundamental shift: from a unified global supply chain to a parallel evolution of regionalization (Region-for-Region) and bloc-based grouping (Bloc-based). In other words, regionalization addresses "market proximity and barrier avoidance," while bloc-based grouping responds to the "deep divisions of political camps." The global automotive industry is entering an era of "multiple blocs in parallel" for supply chains. This will be the most profound and long-lasting structural change in the next decade.

Ⅳ. Supply Chain Strategy Upgrade: Localization and Diversification

Amid the uncertainties of geopolitics, the "global supply chain" is gradually evolving into a "regional supply chain." More and more automakers are choosing to build factories near key markets, both to be closer to consumers and to avoid potential trade barriers.

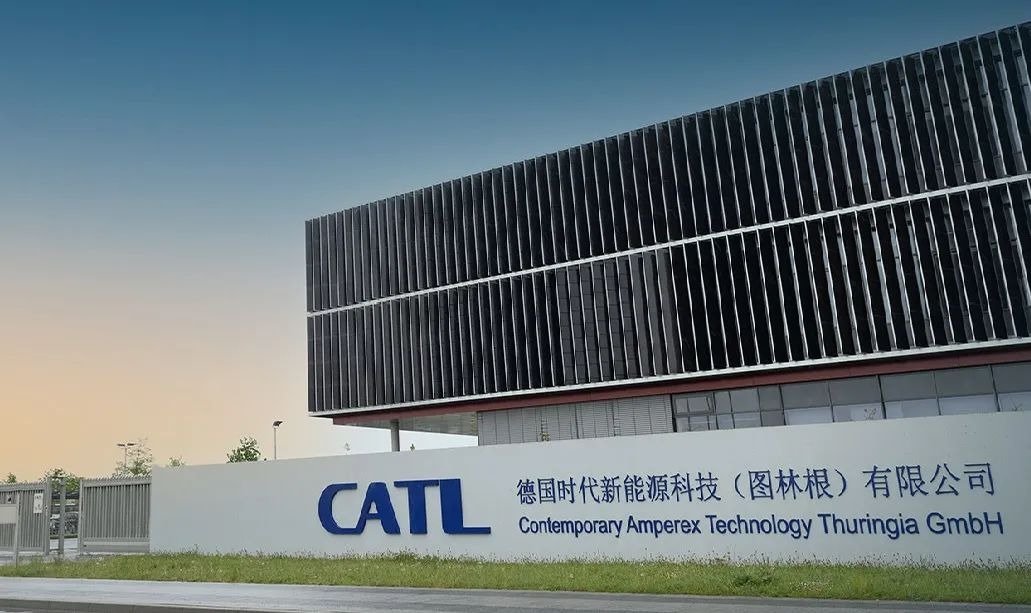

CATL has established two key bases in Europe, in Germany and Hungary, becoming a critical pivot in the globalization of China's battery industry. BYD has started constructing a factory in Thailand with an annual production capacity of 150,000 vehicles and is investing over $1 billion in Indonesia to build a "nickel—battery—vehicle" integrated project.

Photo source: CATL

Meanwhile, Japanese and Korean automakers are deepening partnerships with "friend-shore" countries like the United States and Canada to strengthen supply chain security. For example, LG and General Motors plan to build a large battery factory in the US, and Samsung SDI has investment projects with Stellantis in Canada. These layouts are seen as a "friend-shoring" strategy to mitigate geopolitical risks and align with local subsidy policies.

Geopolitical factors are pushing "supply chain security" from being a backstage issue to a forefront concern, becoming a new competitive barrier. The European Union, in its proposed Critical Raw Materials Act, has set a target for 2030: at least 40% of strategic raw materials consumed annually must be processed within the EU, with a recycling capacity share of at least 15%. The US IRA also emphasizes an increased proportion of "friend-shore" sourcing for critical minerals.

These institutional reforms demonstrate that the global supply chain is shifting from an "efficiency logic" to a "security logic." For the automotive industry, the companies that can build resilient, reconfigurable supply chain networks with geopolitical compliance capabilities will be the ones most likely to seize the competitive advantage in the future.

Ⅴ. China's Role: From Cost Center to Resilience Center

For China's automotive industry, this is both a challenge and an opportunity.

The challenge lies in the fact that overseas investments face political and social resistance, and key technology and resource supply chains are subject to external restrictions.

The greater opportunity, however, is that China possesses the world's most complete manufacturing and supply system, enabling it to build a "multipolar supply chain" globally. CATL is establishing a "three-polar" system across Europe, the US, and Asia, while BYD, Chery, and Geely are also building new networks through factory construction, partnerships, and investments to establish "localized production + global responsiveness."

Chinese automakers and supply chain companies are shifting from a "cost-driven" model to a "resilience-driven" one, transitioning from "manufacturing chains" to a dual management of "security chains + value chains." This means that China is not only the world's largest single automotive market but is also becoming a key pillar of global industrial security and the new order.

Ⅵ. The Rebalancing of Global Automotive Industry

It is clear that the global automotive industry has entered a completely new competitive landscape: Electrification and intelligence are the technological driving forces; geopolitics and supply chain security are the real challenges; and the triangular rivalry of "Shanghai—Silicon Valley—Munich" is defining the strategic order for the next decade. This is not just a shift in geographic centers, but a threefold reshaping of rules, speed, and ecosystems. For China, this reshaping represents a historic leap from being the "largest single market" to becoming a "core power center."

This is Tina's Talk.

In the next episode, we'll discuss EP4: From the Largest Market to the New Global Chain Leader—The Underlying Logic of China's Automotive Industry Leap.

Written by Xiaoying Zhou — CEO and Editor-in-Chief, Gasgoo International