The New Global Automotive Triangle: Shanghai, Silicon Valley, and Munich

In recent years, the global electric vehicle market has witnessed an unprecedented wave of growth, with China emerging as a leader in global electric vehicle development. Market research data shows that sales of new energy vehicles in China have maintained rapid growth over the past five years, accounting for more than 60% of the global market share. As electric vehicle sales continue to surge, power battery systems face mounting challenges: how to accelerate development and product launch while simultaneously boosting energy density, extending driving range, reducing costs, and enhancing safety; and how to align regional battery technology innovations with complex global market access standards. These have become critical issues at the forefront of industry attention.

As a leading global supplier of advanced materials and adhesives, Henkel is leveraging innovative materials, modeling and simulation capabilities, as well as globalized services to help automakers and battery manufacturers accelerate R&D process, improve efficiency, and support large-scale expansion in international markets. Recently, we held an in-depth conversation with Mr. Tobias Knecht, Henkel's Head of Global Market Strategy for the New Energy Vehicle segment of Henkel's Automotive Components business, and Mr. Austin Sun, Head of Product Development for the Asia-Pacific region. Together, we explored how Henkel provides comprehensive support to accelerate the development of the electric vehicle and battery industries.

Efficiency Revolution: From Battery Design Innovation to Holistic Material System Advancement

"If we have to summarize the new trends and demands in the current battery area with one word, it would be 'efficiency'." Tobias Knecht stated unequivocally at the outset, "Whether it's volumetric utilization, weight efficiency, fast-charging capability, driving range, manufacturing costs, or development speed, the entire industry is striving for more efficient battery systems across the board."

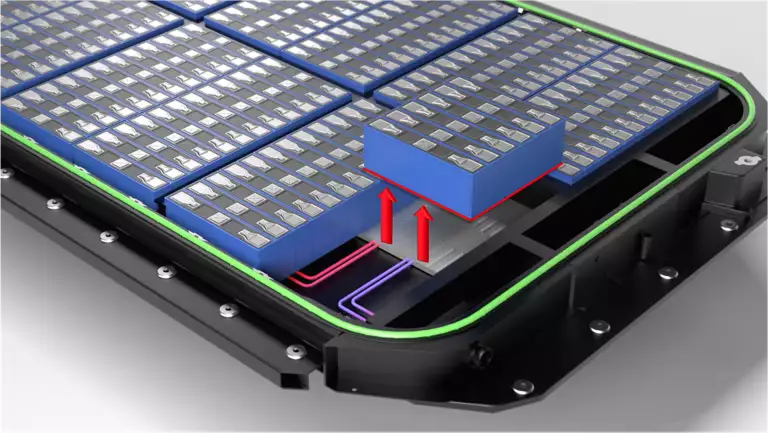

Such pursuit of efficiency is driving fundamental changes in structural design of batteries. From the traditional "Cell to Module" (CTM) to today's mainstream "Cell to Pack" (CTP), then to the cutting-edge "Cell to Chassis" (CTC), and further to "Cell to Body" (CTB), each step of evolution marks a significant simplification of supporting structures between modules and the number of components, a remarkable improvement in energy efficiency such as fast charging and range, as well as superior cost efficiency.

Image source: Henkel

However, while simplifying battery pack structural design offers significant performance and cost benefits, it also poses substantial challenges for material systems and adhesive technologies.

Tobias explained, "Previously, we might only need to provide simple gaskets to bond the battery upper cover to the battery pack shell, which only needed to have sealing properties and a certain degree of elasticity. But now, when cells are directly integrated into the battery pack or even the vehicle body structure, traditional bolt connections and mechanical fixing methods are insufficient. Therefore, our adhesives must have multiple functions: provide sufficient structural strength, maintain necessary elasticity, and also have properties such as thermal conductivity to enhance battery performance."

In addition to the challenges brought by battery structural design, battery recycling after a vehicle reaches end-of-life has also become a focus in the industry. How can batteries bonded with high-strength adhesives be efficiently and reliably disassembled to ensure effective recycling of their valuable materials? Such issues place higher demands on the capabilities of material and adhesive suppliers. Tobias emphasized, "Nowadays, the function of adhesives is gradually evolving from single sealing or fixing to the comprehensive solution integrating different functions (e.g., structural bonding + elasticity, structural bonding + debonding, structural bonding + thermal conductivity."

Henkel has been deeply rooted in adhesive technologies and functional materials for over a century, consistently investing in next-generation adhesives, thermal interface materials, and coating innovations to deliver comprehensive, future-ready solutions for its customers. For instance, in response to the evolving structural designs of battery packs, Henkel has introduced a novel structural adhesive sealing solution that uniquely combines elasticity with high structural strength—properties traditionally difficult to achieve in a single adhesive formulation. To address thermal management and battery safety, Henkel offers a portfolio of advanced materials, including thermally conductive adhesives (TCAs), flame-retardant compounds, safety coatings, and tailored system solutions, enabling both efficient heat dissipation and robust structural integrity.

Lightweighting and cost control are also core aspects of material innovation. Henkel’s hybrid adhesive solutions enable the integration of advanced materials such as engineered plastics into battery pack designs, offering customers greater flexibility in material selection to achieve significant weight and cost reductions. Moreover, addressing the growing need for serviceability and sustainability, Henkel offers solutions with controlled debonding capabilities, allowing battery cells to be more easily removed from the pack during repair or recycling. This enhances recycling efficiency and optimizes battery lifecycle management.

Henkel's solutions with controlled debonding capabilities; Image source: Henkel

In addition, the functional coatings provided by Henkel can also be applied to the surfaces of cooling plates or battery cells, applied through efficient printing processes and light-curing technology, which is significantly more energy-efficient compared to traditional powder coatings. Generally, these innovative materials and adhesive solutions not only meet battery performance and safety requirements, but also support global customers' strategic goals in terms of cost, lightweighting, recycling, and sustainability.

Digital Twin: Accelerating Battery Development Through Modeling, Simulation, and Virtual Material Cards

As the electric vehicle market continues to scale, consumer demands for range, safety, charging speed, and reliability are rising rapidly, driving industry competition to pivot increasingly toward product iteration speed. Achieving rapid development and shortening R&D cycles have become urgent issues for automakers and battery manufacturers. On the one hand, the introduction of new materials, new processes, and new structures continues to increase system complexity, making traditional linear development models unable to support more compact mass production schedules. On the other hand, projects often need to go through multiple stages from proof of concept to mass manufacturing, including design, simulation, testing, validation, and manufacturing collaboration. An excessively long cycle in any stage may delay the overall time to market and miss the market window.

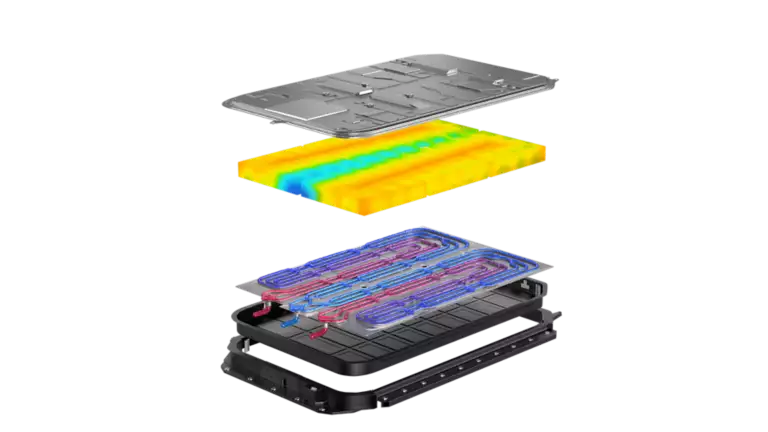

As a key player in the battery R&D and manufacturing value chain, Henkel has positioned the key to acceleration at the very outset of battery development (the design phase) and extended its innovation into the virtual realm. By leveraging advanced modeling and simulation capabilities, Henkel is significantly accelerating material design and R&D processes. Tobias said, "In the early stage of battery pack R&D, customers usually first establish digital design models, including CAD models and simulation systems, to test the structural performance, charging behavior, and thermal management effectiveness of the battery pack. Based on processes of customers, Henkel has also established in-house modeling and simulation capabilities. Through digital twin technology, adhesives can be simulated in a virtual environment before sample production, allowing customers to verify material performance in the early design stage without relying on physical samples."

Battery Modeling and Simulation; Image source: Henkel

Henkel's "Virtual Material Cards" are the concrete manifestation of such capability. Tobias explained that virtual material cards are actually the "digital replicas" of adhesives, containing all key performance parameters such as the structural, thermal and rheological properties of adhesives. Battery design engineers can import these virtual materials into simulation systems at the product concept stage to conduct comprehensive performance verification.

The transformative power of this approach lies in fundamentally reshaping the material selection timeline and dramatically accelerating the R&D cycle. "In the traditional process, we first need to complete the testing and development of adhesives in the laboratory, then send the samples to customers, who test them and feedback on whether the performance is qualified. Such process often takes weeks or even months", Tobias compared. "Now, with the help of AI technology, modeling and simulation, we can create a 'virtual adhesive' and obtain various key parameters in just a fraction of the time. Customers can directly call this virtual material card in their CAE (Computer-Aided Engineering) software, and apply this material still in the 'concept' stage to the simulation testing of next-generation battery packs."

Henkel's modeling and simulation capabilities span three critical areas of battery development: First, structural and crash simulation, which assesses the performance of adhesives and battery packs under mechanical stresses such as collisions and vibrations. Second, thermal performance simulation, which evaluates how different thermally conductive adhesives influence heat dissipation and fast-charging efficiency in battery packs. Third, safety performance simulation, which models the protective capabilities of Henkel's flame-retardant materials and safety coatings during extreme thermal events.

In other words, through Henkel's modeling and simulation solutions, customers can not only make scientific decisions in advance regarding material and adhesive selection and process design, fundamentally reducing trial-and-error costs and iteration time, and shortening the development cycle; they can also identify potential issues during the design phase. Through thermal runaway simulation, customers can evaluate the behavior of adhesives and functional coatings under abnormally high temperatures during the design phase, thereby optimizing material solutions in advance and improving battery safety.

More importantly, Henkel combines its advanced modeling and simulation capabilities with a global network of Battery Engineering Centers. Real-world material performance data, which is gathered through robotic dispensing systems and rigorous laboratory testing, is fed into machine learning algorithms to continuously refine and optimize simulation models. Such combination of real and virtual environment testing can ensure that simulation data is highly consistent with actual applications, providing customers with reliable design references.

Image source: Henkel

In addition, this method helps customers achieve consistent design globally. Whether customers launch projects in the Asia-Pacific, European, or North American markets, digital twin tools can ensure the consistency of material performance data and development processes, providing design and egineering support for global deployment.

Trustful Collaboration: Local Innovation & Global Impact

As a deeply globalized enterprise, Henkel has a clear insight into the technological trends and industrial characteristics of electric vehicles in different regional markets, and on this basis, promotes cross-regional technological and ecological collaboration.

Austin Sun pointed out in the interview that unlike the European and North American markets, which focus on long-term reliability, emphasize stricter validation cycles and higher safety standards, the Chinese market presents a unique "triple-driver" mechanism: extreme speed of innovation iteration, stringent cost control pressure, and a highly flexible supply chain collaboration ecosystem. This unique market environment has positioned China as one of the key innovation hubs for Henkel's global electric mobility business.

In response to the urgent demand in the Chinese market for fast charging technology, high energy density, and integrated battery pack design, Henkel has established a deeply localized development capabilities in China. Austin Sun introduced that, in view of China's complex geographical and climatic conditions, Henkel has developed battery pack material solutions adapted to the cold environment in northern China and the high-temperature environment in southern China; in addition, Henkel focuses on developing next-generation hybrid adhesives, high-reliability sealing materials, and thermal conductive adhesives (TCA). These solutions not only fulfill essential structural bonding requirements but also deliver efficient thermal management capabilities to address extreme thermal loads encountered during fast-charging scenarios.

It is worth noting that the innovations developed locally by Henkel's Automotive Components business in China are not limited to serving the Chinese market. Austin Sun mentioned that Henkel has co-developed a thermal conductive adhesive (TCA) with a customer in the Chinese market. After completing local verification and certification, it was successfully deployed to the customer's plants in Southeast Asia and Europe, with consistent material formulas, quality and performance. As comprehensive material certification and mass production verification have been completed in China, the time for large-scale introduction into overseas plants has been significantly shortened. This approach provides critical support for customers' international expansion.

To enable this "local development with global deployment" model, Henkel leverages its integrated R&D teams and battery testing centers across North America, Europe, and the Asia-Pacific region. This global network allows customers worldwide to share unified material platforms, quality systems, and testing standards. The architecture ensures that rapid local development remains fully aligned with global benchmarks, while empowering global customers to deploy consistent material systems across cross-regional manufacturing lines. As a result, Henkel has become a trusted strategic partner for Chinese EV and battery enterprises as they expand onto the global stage.

Powering Global Expansion: Empowering Chinese Enterprises to Take Center Stage on the World Arena

As China's EV industry chain matures and domestic market competition intensifies, expanding overseas has become an inevitable strategic move for Chinese battery makers and automakers. In this globalization process, Chinese enterprises have demonstrated unique competitive advantages while also facing multiple challenges.

Austin analysis suggests that the advantages of Chinese EV enterprises in global expansion are, on the one hand, reflected in the battery industry chain: Chinese battery manufacturers are very mature in battery design and engineering capabilities, with rich experience in factory construction and manufacturing line replication, enabling them to quickly replicate their successful models in China to the global market; on the other hand, Chinese enterprises have demonstrated excellent capabilities in the layout of global raw material supply chains. "They can acquire resources globally, strengthen their own value chains, and distribute products more efficiently worldwide," said Austin Sun. This globalized supply chain footprint has laid a solid foundation for Chinese enterprises venturing overseas.

However, it does not mean that the path for Chinese enterprises to go overseas will be smooth. Austin Sun candidly noted that the greatest challenge lies in aligning Chinese battery manufacturers' designs with the diverse regulatory requirements of different regions worldwide, particularly in Europe and North America, where stringent regulations govern environmental protection, sustainability, and battery recycling. These differences pose severe challenges on Chinese enterprises in product design and material selection. In addition, in the process of globalization, Chinese enterprises need to break free from geographical restrictions and deeply understand local market regulations, stability requirements, and consumer expectations.

In this context, partnering with a trusted local ally capable of delivering large-scale support can significantly amplify efficiency, making Henkel, with its established global footprint, an ideal partner for Chinese enterprises expanding overseas.

Henkel has been deeply rooted in the global market for years, and has a profound understanding of the regulations and standards of different countries. This localized expertise enables Chinese enterprises to align precisely with local regulations, thereby achieving greater efficiency during the project introduction phase. "We can help battery manufacturers in the Asia-Pacific region quickly develop batteries that meet regional regulatory requirements, accelerating their smooth implementation and large-scale mass production," said Austin Sun.

In addition to compliance support, Henkel's core value proposition also lies in its comprehensive product portfolio, which can provide solutions covering the entire process from battery design to delivery. As a globally trusted supplier, Henkel not only provides materials and adhesive products, but also offers comprehensive technical support and services.

It is attributed to Henkel's extensive global innovation footprint and supply chain network. "Whether in China, Europe, or North America, we leverage our strong local innovation capabilities and infrastructure to support customers' new designs and projects, delivering consistent, high-quality material solutions across different markets," said Austin Sun.

Conclusion:

Looking ahead, the New Energy Vehicle segment of Henkel's Automotive Components business aims to accelerate the large-scale adoption of zero-emission mobility and solidify its role as a trusted global partner for automakers and battery manufacturers. "Our vision is to promote the global scaling of electric vehicles while supporting customers from the Asia-Pacific market and China in expanding their business in international markets," said Tobias Knecht.

Austin Sun added, "We hope to explore the forefront of battery technology with our customers, develop new battery materials and technologies, and achieve innovative breakthroughs in next-generation battery technology."

As the global electric vehicle market continues to expand, Chinese enterprises will find increasingly broader opportunities for overseas growth. Henkel, with its century-long expertise and knowhow in the area of materials science, combined with forward-looking digital tools (such as virtual material cards and modeling & simulation), as well as a truly global network of Battery Engineering Centers, is committed to becoming the "enabler" and "booster" for Chinese partners to overcome geographical barriers, accelerate product launch, and successfully achieve global scaling objectives.

Gasgoo not only offers timely news and profound insight about China auto industry, but also help with business connection and expansion for suppliers and purchasers via multiple channels and methods. Buyer service: buyer-support@gasgoo.com Seller Service: seller-support@gasgoo.com

All Rights Reserved. Do not reproduce, copy and use the editorial content without permission. Contact us: autonews@gasgoo.com.