Solid‑state batteries, seen as the core of the next generation of traction batteries, have reached a key milestone: the national standard "Solid‑State Batteries for Electric Vehicles, Part 1: Terms and Classification" has been released for public comment. It is China's first national‑level draft standard dedicated to automotive solid‑state batteries.

Image source: screenshot of the National Standard of the People’s Republic of China

Years of confusion born of fuzzy definitions and missing standards—where "semisolid" and "quasi‑solid" blurred together and marketing claims ran ahead of science—will be systematically corrected under this clearer national framework. Beyond giving industry a unified technical rulebook, the standard sets a well‑marked starting line for the race from lab breakthroughs to industrialization.

The national standard sets the yardstick

The most notable change in the draft for public comment is a fresh definition of battery categories. Based on how ions are transported within a cell, the standard divides batteries into three classes: liquid batteries, hybrid solid‑liquid batteries, and solid‑state batteries.

This explicitly removes the widely used yet ill‑defined "semisolid" label, and formally establishes "hybrid solid‑liquid" as a clear technical class between liquid and all‑solid‑state.

The move partly answers a long‑running industry debate over whether semisolid is a transitional solution or a marketing tactic. By giving "hybrid solid‑liquid" formal status, the discussion shifts from semantics to practical questions of performance, cost, and commercialization pathways.

The clause with the most technical heft sets a strict threshold for what counts as solid‑state: in a 120°C heating test, mass loss must be no greater than 0.5%.

Image source: China Society of Automotive Engineers

That numeric bar is tougher than the group standard issued by the China Society of Automotive Engineers in May. The drafting team explains that while an ideal solid‑state battery should contain no liquid electrolyte, some solid electrolytes may undergo slight decomposition at high temperatures, hence a small mass loss allowance.

Quantifying the cutoff creates a hard technical boundary between "all‑solid‑state" and "hybrid solid‑liquid," directly curbing over‑reach in marketing.

Beyond core definitions and criteria, the standard adds a fine‑grained, multi‑dimensional classification—an official framework for comparing the many technical routes side by side.

By electrolyte type, solid‑state batteries are grouped as sulfide, oxide, polymer, halide, and composite‑electrolyte.

By conducting ion, they include solid‑state lithium‑ion and solid‑state sodium‑ion, among others. By application, they split into high‑energy and high‑power solid‑state batteries.

This structure helps firms focus on defined routes instead of spreading resources thin, and lets automakers choose precisely based on model positioning and performance needs—speeding product matching and integration.

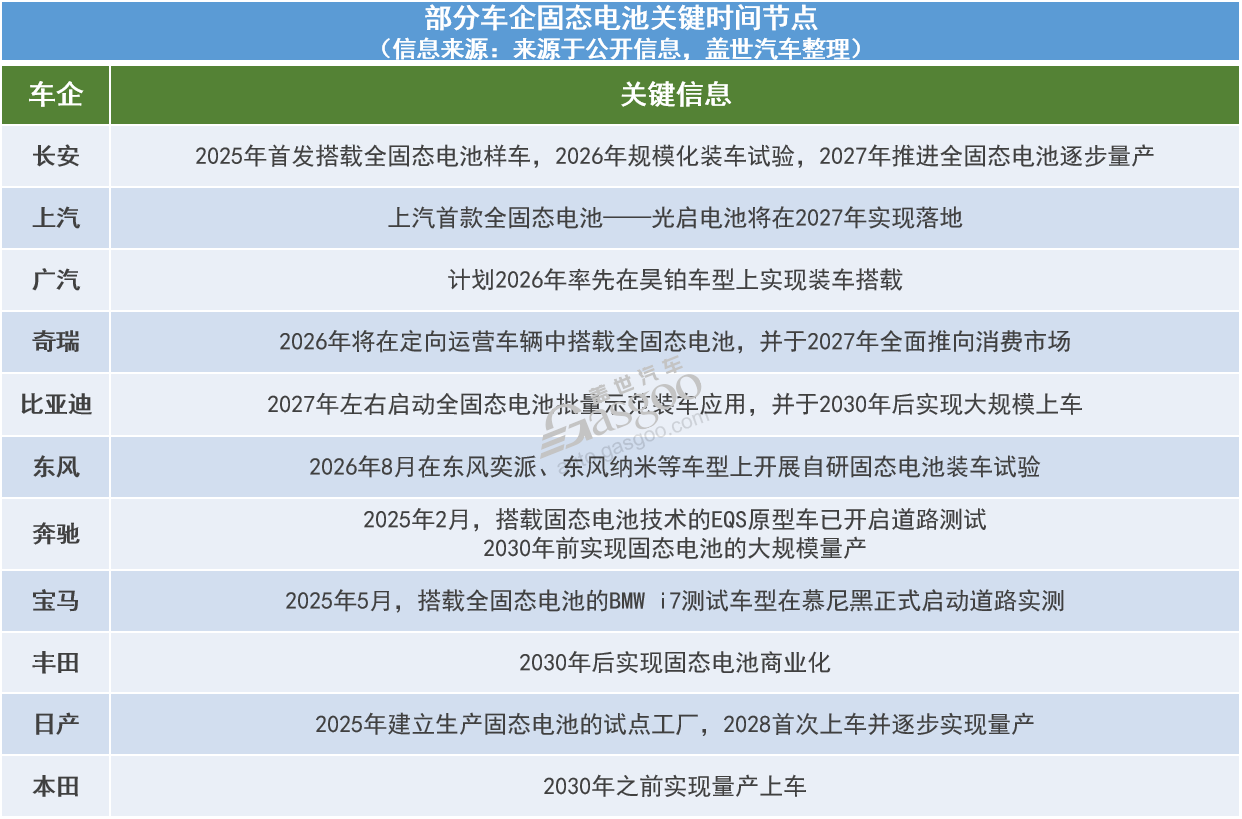

The industry’s race

With the national standard’s clear coordinates, mainstream players’ technology paths and strategies can be assessed more transparently.

Among those aiming straight for all‑solid‑state, Toyota is pursuing sulfide‑based solid electrolytes. It has publicly targeted mass production of all‑solid‑state batteries with energy density of 450–500 Wh/kg, and plans to launch the first production model using them in 2027–2028.

CATL Chairman Zeng Yuqun has been unequivocal: "Solid‑state batteries are not a multiple‑choice question—they're compulsory." CATL's all‑solid‑state program has reached technology readiness level 4, with plans to reach levels 7–8 by 2027 and begin pilot‑scale production, followed by large‑scale mass production in 2030.

For companies doubling down on the "hybrid solid‑liquid" reality, such as SVOLT Energy and Dongfeng Motor, the play is to commercialize quickly within a defined lane and optimize performance and cost. In November, SVOLT began small‑batch trial runs of its first‑generation semisolid (hybrid solid‑liquid) batteries on a 2.3 GWh mass‑production line, and plans to supply the next‑generation BMW MINI.

The national standard acts as a common yardstick, making announced progress and production timelines more comparable—and more serious.

On the hybrid solid‑liquid volume race, Dongfeng Motor says its self‑developed solid‑state battery reaches 350 Wh/kg and is slated for mass production and vehicle installation in September 2026, with model range expected to top 1,000 km.

SVOLT Energy, Changan Automobile and others have also set their validation schedules. With the standard in place, comparisons become more standardized, and the focus shifts from "is it solid‑state" to—within clear categories—whose performance is stronger, whose costs are lower, and whose safety is higher.

Whatever the chosen route, companies cannot dodge the core engineering challenges underscored by the standard. At the World Power Battery Conference in November, Wan Gang, president of the China Association for Science and Technology, pointed to three hurdles for all‑solid‑state industrialization: materials innovation, process breakthroughs, and the cost trap.

Industry insiders note that sulfide electrolytes react easily with air, oxides suffer high interfacial impedance, and polymers lag in energy density—there’s no "all‑rounder" yet. On manufacturing, yield rates in key steps—such as uniformity in dry‑process electrode coating and densification of solid‑electrolyte films—can be below 30%.

On cost, current solid‑state batteries run three to five times that of liquid systems, and will need scale and supply‑chain redesign to fall meaningfully. Clear terms and classification lay the groundwork for subsequent test protocols addressing performance, safety and cycle life.

Conclusion:

A square pouch cell with energy density of 480 Wh/kg has passed stringent nail‑penetration tests. Produced by Xinjie Energy, it has secured customer validation and batch applications in eVTOL aircraft and high‑end robotics.

Meanwhile in Yibin, Sichuan, China’s first sulfide all‑solid‑state pilot line is about to enter service; CATL has signed agreements to secure at least 626,000 tons of new anode current‑collector materials—an early move to enable solid‑state production at scale.

As the "Solid‑State Batteries for Electric Vehicles" national‑standard series rolls out, a rule set spanning the full value chain—from materials and cells to system applications—is taking shape first in China.