US: Ford uses animation technology to aid global workers

The Detroit News (Dearborn) - Ford Motor Co. is using a Hollywood-style animation technique to improve worker safety.

The automaker said Tuesday it has developed a global avatar of a worker to help it build vehicles the same way the world over, even though workers' sizes can vary significantly.

Ford's "global manikin" was developed from size and shape data gathered from six assembly plants around the world.

That led to creation of a female avatar who is 5 feet 4 inches tall, but with large male hands, said Allison Stephens, Ford ergonomics specialist with Vehicle Operations Manufacturing Engineering.

The size reflects that workers in many parts of the world are smaller than in other nations, but the big hands are to make sure a larger German or North American assembly line worker can grab the necessary part and perform the job.

Under CEO Alan Mulally, Ford has pursued a strategy to build and sell vehicles everywhere with as many common parts and manufacturing practices as possible.

Ford, like most automakers, has used digital modeling for years to design workstations that are as ergonomically correct as possible, to reduce strain injuries.

But the automaker wanted to take the simulations, through its Jack and Jill digital models, a step further. So it created "motion capture labs" in Dearborn and in Merkinish, Germany.

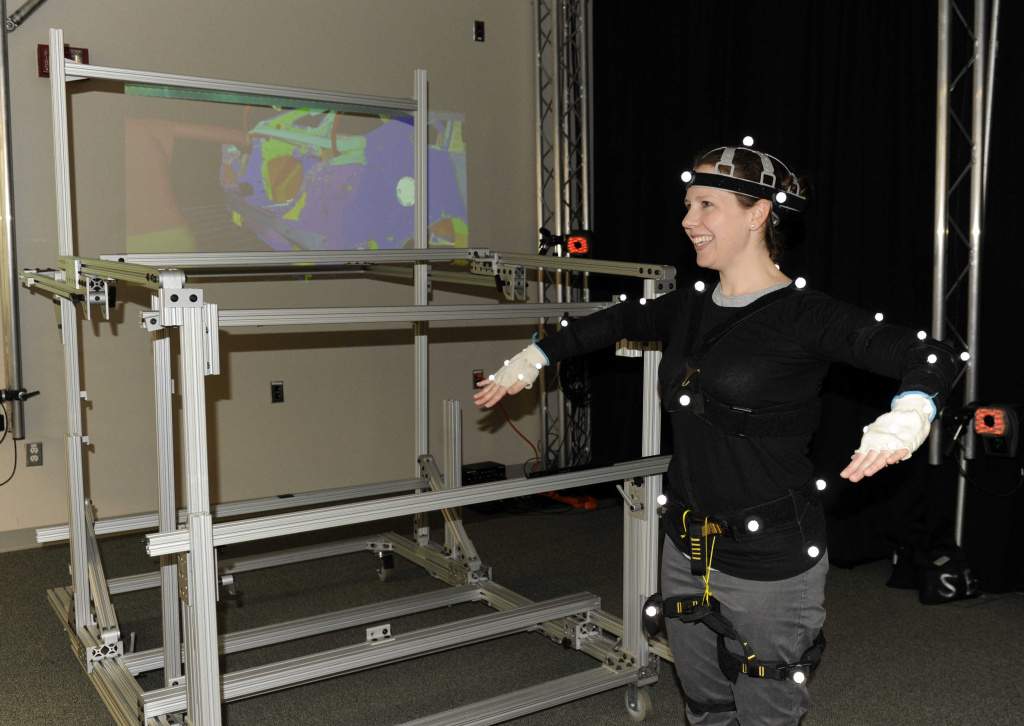

In the labs, real people are suited up with reflective tape on key joints and parts of the body and their movements are captured by 15 cameras. The data is fed into the digital human models to make their movements even more realistic. The basic technique is used in computer animated films and video games.

"The result is workers are not going to get the injury and consumers will get better quality vehicles," Stephens said.

Since January this new technique has been implemented, with much of the work centered on the hybrid and electric versions of the new Ford Focus, said Mary Heck, manufacturing ergonomics engineer.

By putting a person in the capture motion lab, it became evident that installing a strut, for example, was a difficult reach for a smaller worker, Heck said. With the help of a UAW worker at the Wayne Assembly plant in Dearborn, that finding led to development of a tool to extend the worker's reach and make the assembly easier. A tall person can choose not to use the aid.

That is the general concept Ford is seeking globally — to design assembly plant workstations where the task can be done by this new global manikin. Each plant tweaks its workstations as necessary, to reflect the regional workforce and the individual plant. Ford wants to share its findings in countries where the work is done by suppliers.

Stephens said that when digital modeling was introduced about a decade ago, ergonomic injuries fell about 80 percent.

Potential problems on the assembly line can be identified two or three years before an operator is exposed to it, Stephens said.

And the work is far from done. Santos, a military-style avatar, is being developed to assess heavy lifting by line workers.

Gasgoo not only offers timely news and profound insight about China auto industry, but also help with business connection and expansion for suppliers and purchasers via multiple channels and methods. Buyer service:buyer-support@gasgoo.comSeller Service:seller-support@gasgoo.com