Gasgoo Awards 2023 receives many applications in powertrain electrification segment

Gasgoo, a global leading automotive industry information service platform, has kicked off the Gasgoo Awards 2023 program. For the Top 100 Players of China's New Automotive Supply Chain, the program will cover ten core segments, namely autonomous driving, smart cockpit, software, automotive chip, artificial intelligence, powertrain electrification, intelligent chassis, body and exterior & interior, low-carbon and new materials, as well as thermal management.

In powertrain electrification segment, the Gasgoo Awards 2023 have attracted multiple companies to apply for the Top 100 Players of China's New Automotive Supply Chain. Here are some details about them.

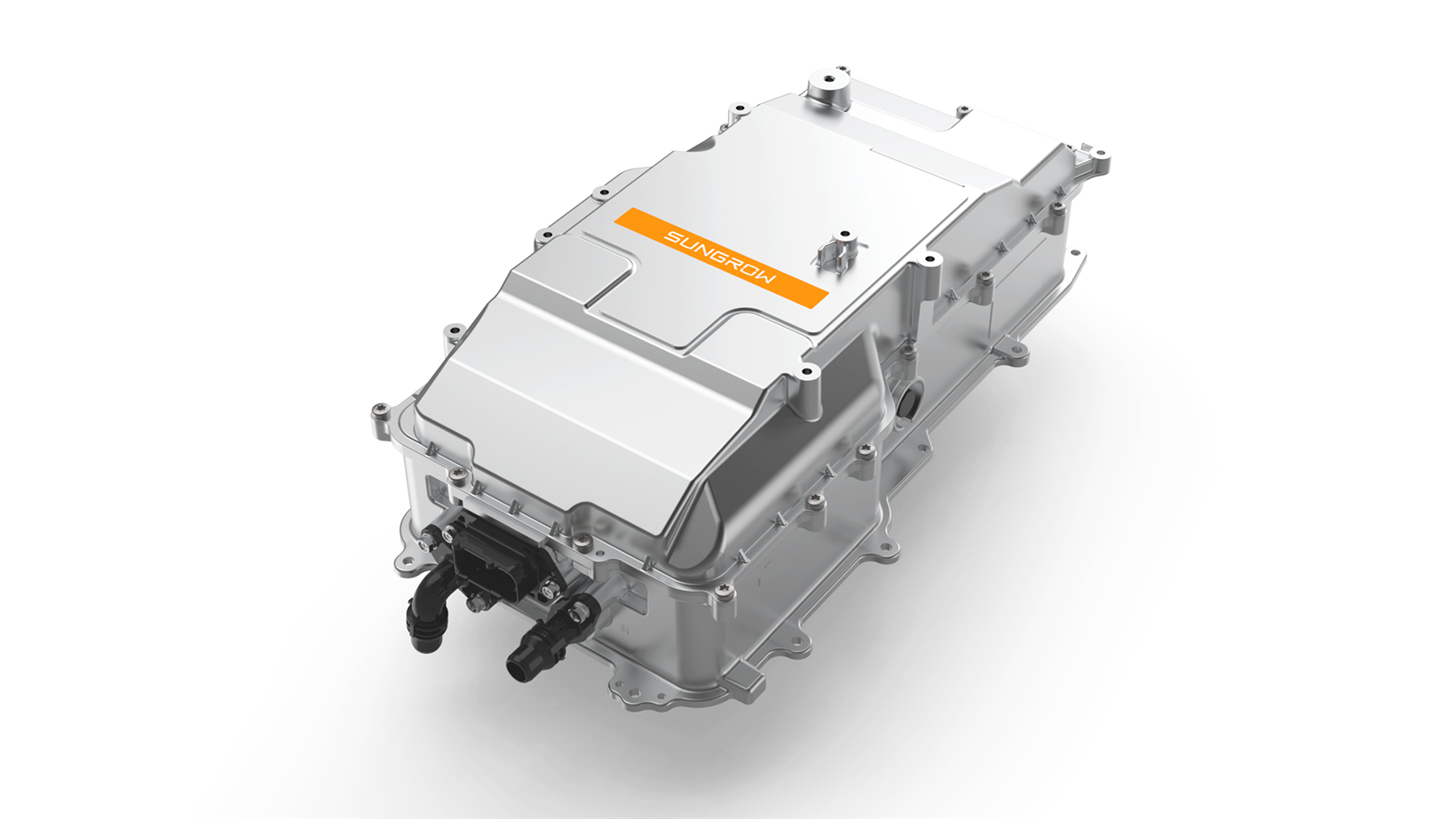

Hefei Sungrow E-Power Technology Co., Ltd.

Description

The HEM3 dual inverter specially developed for hybrid vehicle models adopts a highly integrated control board solution, which can achieve precise control of dual motors by a single multi-core main control chip; At the same time, the software is developed based on the model, the Software architecture conforms to AUTOSAR, and has the ability to upgrade to ASIL-D Functional safety level. EMC meets the requirements of Class 3 on load, combined with system application scenarios, meets 10g vibration, and has a protection level of IP68, making vehicle applications safer.

Unique advantages

Adopting a new discrete device parallel technology, by paralleling different numbers of power devices, flexible power expansion can be achieved, adapting to different vehicle power requirements, and saving the development cycle and cost of the entire vehicle.

Application

Dedicated Hybrid Transmission

Prospect

Hybrid electric vehicles have advantages in environmental protection, economy, technological innovation, and efficient energy conservation, playing an important role in promoting the sustainable development of the automotive industry. In the future, hybrid vehicles will become one of the mainstream products in the global automotive market and an important direction for the development of China's automotive industry. The platform-based motor controller developed by Sungrow E-Power can meet the mainstream hybrid architecture in the market and has broad application prospects.

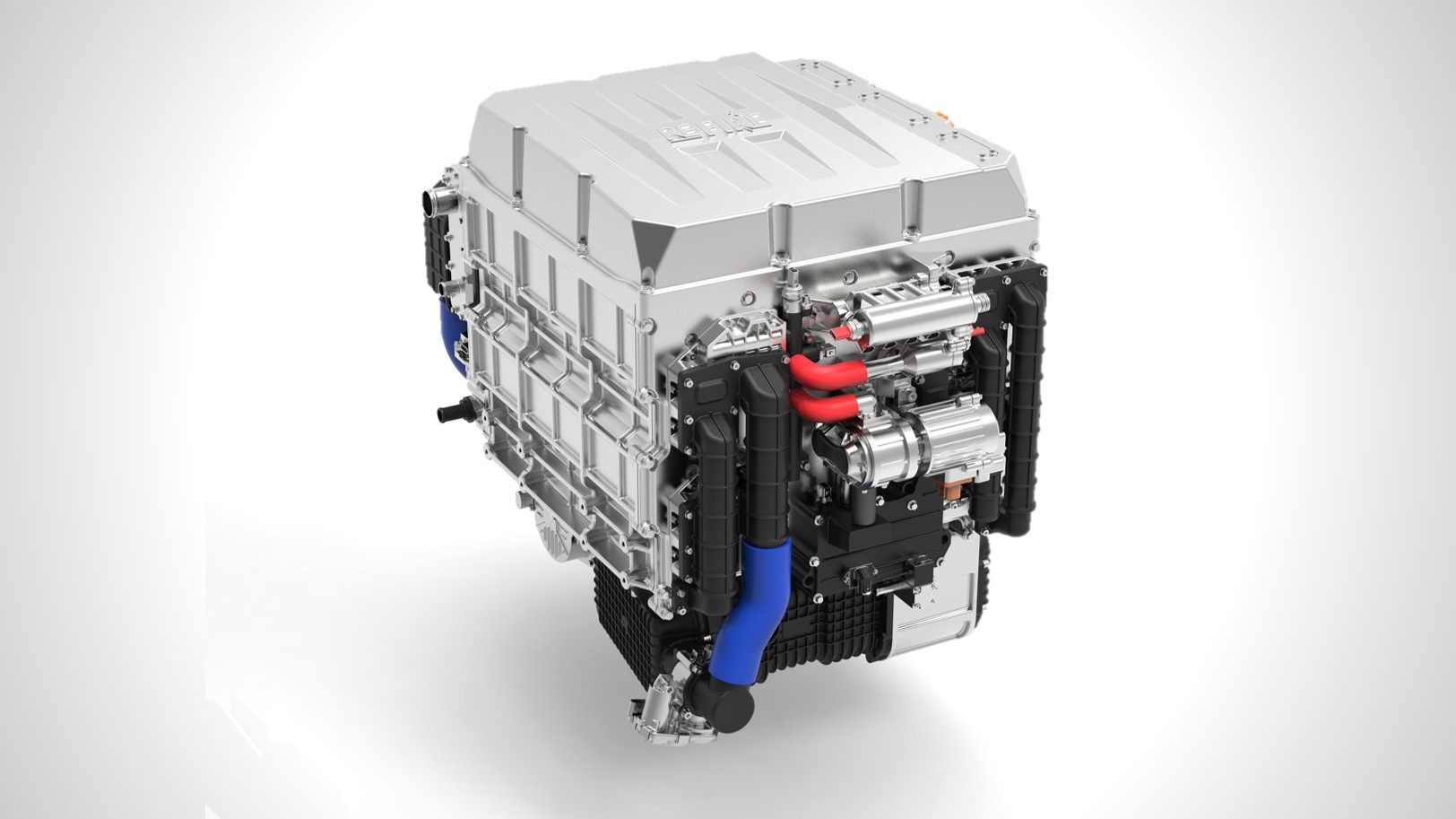

Shanghai REFIRE Group Co., Ltd.

Product: REFIRE Group PRISMA Series Fuel cell system

Description

REFIRE Group PRISMA Series Fuel Cell Systems: REFIRE Group has developed two generations of fuel cell systems, ranging from 32 kW to 220 kW (expandable to 260 kW). The systems enjoy advantages in key technical indicators, with high cost-effectiveness and reliability. While providing clean power for commercial vehicles, the systems can meet requirements for sustained high-power output, long-distance operation, and wide temperature range. Currently, these fuel cell system have been applied in the field of fuel cell vehicles, especially in material handling, distributed power generation, and other areas. In addition, REFIRE Group actively expand application scenarios in aviation, maritime, construction machinery, and other fields. Backed up their excellent comprehensive performance, REFIRE Group’s fuel cell system products have been awarded the ECE R10 certificate by TÜV Nord and the "Performance Verification Certificate" by TÜV Rheinland, which is the first-ever certificate TÜV Rheinland has awarded to a fuel cell company.

Unique advantages

1) Sustainable Technological Competitiveness with Products at Its Core - Global R&D team: REFIRE Group has R&D centers in Shanghai and Vancouver, with R&D personnel accounting for over 30% of the total number of employees. Among them, nearly half are highly educated individuals with master's or doctoral degrees in fields of electrochemistry, materials, mechanical power, control, and so on. - Class-leading R&D hardware: REFIRE Group boasts 31 laboratories certified by the China National Accreditation Service for Conformity Assessment (CNAS) and more than 100 sets of advanced instruments and equipment, which ensure comprehensive development, testing, verification, and trial production capabilities for systems, key components, vehicle power systems, and engineering sample vehicles. - Complete chains from materials, components, products to applications: REFIRE Group has achieved independent development and large-scale production of key components such as fuel cells, MEAs, bipolar plates, hydrogen circulation systems, and DC/DC converters. Through independent innovation and technological iteration, REFIRE Group continuously move fuel cell vehicles towards greater reliability, more stable performance, stronger safety and greater cost-effectiveness by upgrading its fuel cell products, with system power, power density, and service life being industry-leading. - Government-level and industry-level honors and recognition: to date, REFIRE Group has been awarded the “National Enterprise Technology Center” by the National Development and Reform Commission; the second batch of national-level specialized and new "Little Giant" enterprise title recognized by the Ministry of Industry and Information Technology of the People's Republic of China; the title of "Enterprise of Single Champion in Manufacturing Industry" by the Ministry of Industry and Information Technology of the People's Republic of China; the title of “National Intellectual Property Advantage Enterprise”; 2021 Shanghai Fuel Cell System Technology Innovation Center and many other national and municipal titles; in addition, REFIRE Group has garnered the First Prize of 2020 China Automotive Industry Science and Technology Progress Award, the First Prize of China Machinery Industry Science and Technology Award, 2022 Shanghai Hardcore Technology Enterprises TOP100, the First Prize of 2022 Shanghai Industry-University-Research Cooperation Excellent Project, the First Prize of 2022 Shanghai Science and Technology Progress, and so on. The high-power fuel cell energy supply equipment independently developed by REFIRE Group has been listed as the first major technical equipment project in the energy field by the National Energy Administration in 2021. As the leading company, REFIRE Technology has collaborated with industry partners to undertake the 2022 “new energy vehicles” key project of the Ministry of Science and Technology of the National Key R&D Program - “commercial vehicles with high-power and long-life fuel cell stacks and engine technology”, continuously innovating core technologies.

2) Build a Open, Collaborative and Win-win Hydrogen Industry Ecosystem - REFIRE Group is committed to building a hydrogen technology ecosystem in collaboration with product-end, energy-end, and scenario-end enterprises, smoothing the chains of technology development and commercial application, and building sustainable business models and scenarios. This includes the establishment of a regional low-carbon logistics micro-ecosystem with local parts companies, Sinopec oil and hydrogen station network, and BESTPATH(shanghai) IoT Technology Ltd, during the first demonstration period of fuel cell vehicle application in Shanghai. In addition, REFIRE Group works with strategic partners such as Sinopec and Shanghai Environment and Energy Exchange to build a large hydrogen application ecosystem, actively participating in transportation energy planning and hydrogen corridor construction, promoting the the Wind-Light-Hydrogen-Storage Integration Project, and carrying out carbon emission reduction methodology development certification, carbon trading system construction, and carbon finance research. - - In addition, REFIRE Group is actively tapping into global markets and establishing a global hydrogen cooperation network. So far, REFIRE Group has successfully launched various fuel cell mini commercial vehicles, buses, and heavy-duty trucks in collaboration with European partners such as Schaeffler Group. Besides, REFIRE Group has been involved in such projects as hydrogen power stations and off-grid charging for fuel cell vehicles and enjoyed a good reputation globally.

3) Widespread and Diversified Application Scenarios: To date, REFIRE Group has expanded its business presence in 20 provinces and 34 cities in China, and multiple overseas markets such as Germany, Switzerland, Croatia, Japan, and Malaysia. REFIRE products and technologies have been applied in diverse hydrogen technology fields, including automobiles, ships, construction machinery, material handling, and distributed power generation. In the automotive filed, REFIRE Group has deployed more than 4,000 fuel cell vehicles, with cumulative clean mileage of over 140 billion kilometers, reducing carbon emissions by over 83,000 tons. -

Application

Based on actual scenario demands, REFIRE Group has developed over 140 models of fuel cell vehicles for various applications, including buses, transport vehicles, refrigerated vehicles, insulated vehicles, sprinkler vehicles, semi-trailer towing vehicles, garbage trucks, dump trucks, and so on. Besides, relying on automotive scenarios, REFIRE Group's fuel cells have been applied in material handling and hydrogen power station products, greatly enriching the application scenarios of hydrogen electric power in daily lives. These fuel cell systems have excelled in safety, reliability, cost-effectiveness and intelligence. To date, REFIRE Group has expanded its business presence in 20 provinces and 34 cities in China, and multiple overseas markets such as Germany, Switzerland, Croatia, Japan, and Malaysia. REFIRE products and technologies have been applied in diverse hydrogen technology fields, including automobiles, ships, construction machinery, material handling, and distributed power generation. In the automotive filed, REFIRE Group has deployed more than 4,000 fuel cell vehicles, with cumulative clean mileage of over 140 billion kilometers, reducing carbon emissions by over 83,000 tons.

Prospect

On March 23, 2022, the Chinese government laid out a medium-and long-term development plan for hydrogen (2021-2035), which position hydrogen as energy. According to the authoritative prediction, by 2030, the scale of the fuel cell industry will exceed trillion-yuan level, and the overall scale of the hydrogen industry will reach 5 trillion yuan. Countries around the world have also introduced relevant supportive policies for hydrogen development. According to data from the International Energy Agency, since February 2021, over 131 large-scale hydrogen development projects have been launched globally, and it is estimated that the global investment in the hydrogen sector will total $500 billion by 2030. Against such a backdrop, REFIRE Group will continue to adhere to the purpose of "becoming the leading hydrogen technology enterprise so that we can help build a sustainable planet", and build the company's competitiveness in technology, products, services, and branding, promoting the diversification and sustainable commercial applications of hydrogen technology. Meanwhile, REFIRE Group will play the role as a hydrogen industry leader, providing support for green development in more industries, sectors, and regions, contributing to the realization of carbon peak and carbon neutrality goals in China.

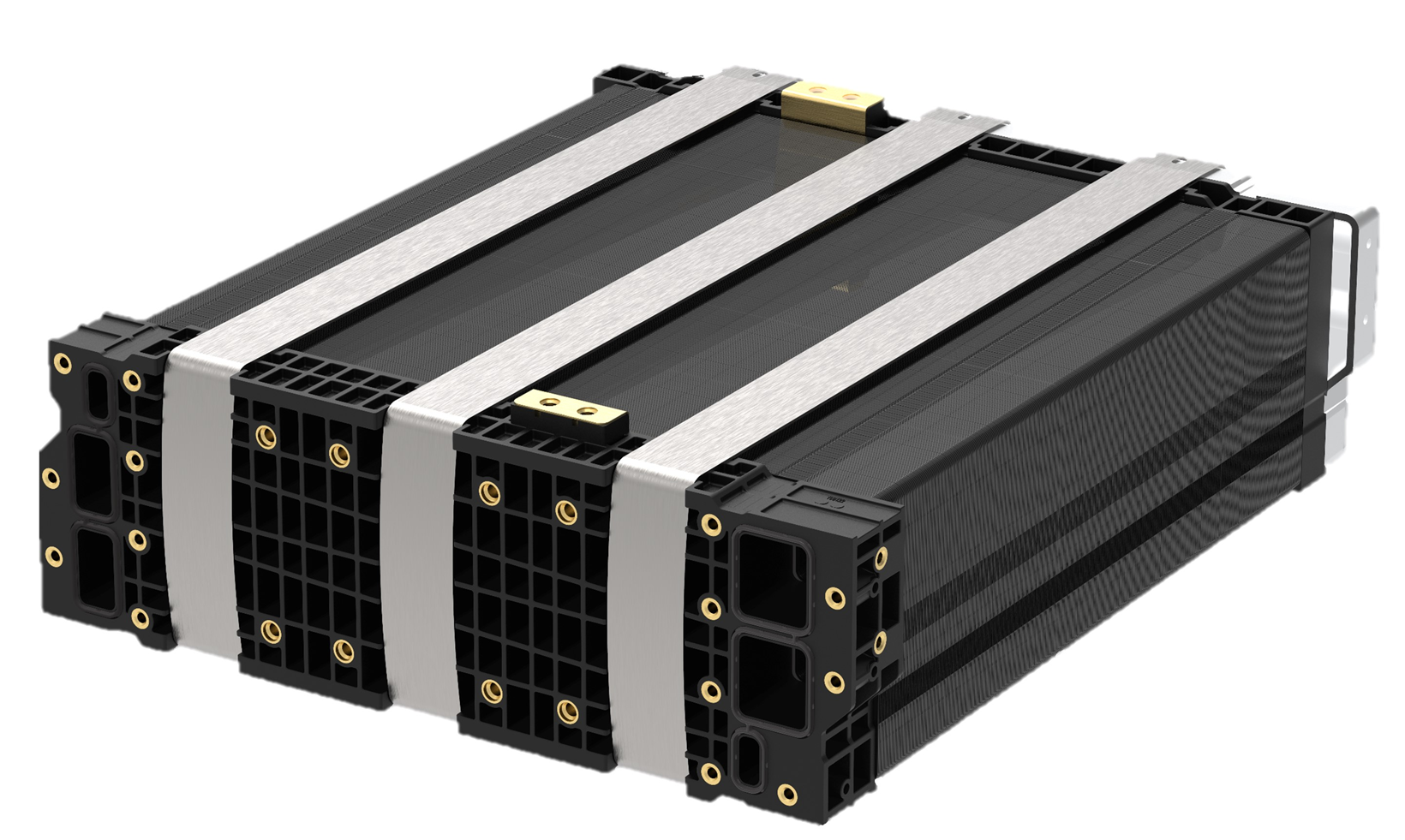

Product: REFIRE Group Electra Fuel cell stacks

Description

REFIRE Group Electra Fuel Cell Stacks: REFIRE Group has independently developed three generations of fuel cell stacks, featuring high performance, long service life, and wide temperature range. They can meet the power demands in the fields of light, medium, and heavy-duty transportation, as well as various application scenarios such as shipping vessels, energy storage and power generation, and construction machinery. Electra stacks are suitable for heavy-duty fuel cell system products. The stack power can be expanded up to 130 kW, with a power density of 4.4 kW/L. With high performance, long service life compatibility, optimized design for manufacturability, and iterative-expandable high flexibility, Electra stacks can support low-temperature startup at -30°C. Relying on its outstanding performance, the Electra fuel cell system has been awarded the "Performance Index Evaluation Certificate" by TÜV Rheinland.

Unique advantages

1) Sustainable Technological Competitiveness with Products at Its Core - Global R&D team: REFIRE Group has R&D centers in Shanghai and Vancouver, with R&D personnel accounting for over 30% of the total number of employees. Among them, nearly half are highly educated individuals with master's or doctoral degrees in fields of electrochemistry, materials, mechanical power, control, and so on. - Class-leading R&D hardware: REFIRE Group boasts 31 laboratories certified by the China National Accreditation Service for Conformity Assessment (CNAS) and more than 100 sets of advanced instruments and equipment, which ensure comprehensive development, testing, verification, and trial production capabilities for systems, key components, vehicle power systems, and engineering sample vehicles. - Complete chains from materials, components, products to applications: REFIRE Group has achieved independent development and large-scale production of key components such as fuel cells, MEAs, bipolar plates, hydrogen circulation systems, and DC/DC converters. Through independent innovation and technological iteration, REFIRE Group continuously move fuel cell vehicles towards greater reliability, more stable performance, stronger safety and greater cost-effectiveness by upgrading its fuel cell products, with system power, power density, and service life being industry-leading. - Government-level and industry-level honors and recognition: to date, REFIRE Group has been awarded the “National Enterprise Technology Center” by the National Development and Reform Commission; the second batch of national-level specialized and new "Little Giant" enterprise title recognized by the Ministry of Industry and Information Technology of the People's Republic of China; the title of "Enterprise of Single Champion in Manufacturing Industry" by the Ministry of Industry and Information Technology of the People's Republic of China; the title of “National Intellectual Property Advantage Enterprise”; 2021 Shanghai Fuel Cell System Technology Innovation Center and many other national and municipal titles; in addition, REFIRE Group has garnered the First Prize of 2020 China Automotive Industry Science and Technology Progress Award, the First Prize of China Machinery Industry Science and Technology Award, 2022 Shanghai Hardcore Technology Enterprises TOP100, the First Prize of 2022 Shanghai Industry-University-Research Cooperation Excellent Project, the First Prize of 2022 Shanghai Science and Technology Progress, and so on. The high-power fuel cell energy supply equipment independently developed by REFIRE Group has been listed as the first major technical equipment project in the energy field by the National Energy Administration in 2021. As the leading company, REFIRE Technology has collaborated with industry partners to undertake the 2022 “new energy vehicles” key project of the Ministry of Science and Technology of the National Key R&D Program - “commercial vehicles with high-power and long-life fuel cell stacks and engine technology”, continuously innovating core technologies.

2) Build a Open, Collaborative and Win-win Hydrogen Industry Ecosystem - REFIRE Group is committed to building a hydrogen technology ecosystem in collaboration with product-end, energy-end, and scenario-end enterprises, smoothing the chains of technology development and commercial application, and building sustainable business models and scenarios. This includes the establishment of a regional low-carbon logistics micro-ecosystem with local parts companies, Sinopec oil and hydrogen station network, and BESTPATH(shanghai) IoT Technology Ltd, during the first demonstration period of fuel cell vehicle application in Shanghai. In addition, REFIRE Group works with strategic partners such as Sinopec and Shanghai Environment and Energy Exchange to build a large hydrogen application ecosystem, actively participating in transportation energy planning and hydrogen corridor construction, promoting the the Wind-Light-Hydrogen-Storage Integration Project, and carrying out carbon emission reduction methodology development certification, carbon trading system construction, and carbon finance research. - - In addition, REFIRE Group is actively tapping into global markets and establishing a global hydrogen cooperation network. So far, REFIRE Group has successfully launched various fuel cell mini commercial vehicles, buses, and heavy-duty trucks in collaboration with European partners such as Schaeffler Group. Besides, REFIRE Group has been involved in such projects as hydrogen power stations and off-grid charging for fuel cell vehicles and enjoyed a good reputation globally.

3) Widespread and Diversified Application Scenarios: To date, REFIRE Group has expanded its business presence in 20 provinces and 34 cities in China, and multiple overseas markets such as Germany, Switzerland, Croatia, Japan, and Malaysia. REFIRE products and technologies have been applied in diverse hydrogen technology fields, including automobiles, ships, construction machinery, material handling, and distributed power generation. In the automotive filed, REFIRE Group has deployed more than 4,000 fuel cell vehicles, with cumulative clean mileage of over 140 billion kilometers, reducing carbon emissions by over 83,000 tons. -

Application

Based on actual scenario demands, REFIRE Group has developed over 140 models of fuel cell vehicles for various applications, including buses, transport vehicles, refrigerated vehicles, insulated vehicles, sprinkler vehicles, semi-trailer towing vehicles, garbage trucks, dump trucks, and so on. Besides, relying on automotive scenarios, REFIRE Group's fuel cells have been applied in material handling and hydrogen power station products, greatly enriching the application scenarios of hydrogen electric power in daily lives. These fuel cell systems have excelled in safety, reliability, cost-effectiveness and intelligence. To date, REFIRE Group has expanded its business presence in 20 provinces and 34 cities in China, and multiple overseas markets such as Germany, Switzerland, Croatia, Japan, and Malaysia. REFIRE products and technologies have been applied in diverse hydrogen technology fields, including automobiles, ships, construction machinery, material handling, and distributed power generation. In the automotive filed, REFIRE Group has deployed more than 4,000 fuel cell vehicles, with cumulative clean mileage of over 140 billion kilometers, reducing carbon emissions by over 83,000 tonnes.

Prospect

On March 23, 2022, the Chinese government laid out a medium-and long-term development plan for hydrogen (2021-2035), which position hydrogen as energy. According to the authoritative prediction, by 2030, the scale of the fuel cell industry will exceed trillion-yuan level, and the overall scale of the hydrogen industry will reach 5 trillion yuan. Countries around the world have also introduced relevant supportive policies for hydrogen development. According to data from the International Energy Agency, since February 2021, over 131 large-scale hydrogen development projects have been launched globally, and it is estimated that the global investment in the hydrogen sector will total $500 billion by 2030. Against such a backdrop, REFIRE Group will continue to adhere to the purpose of "becoming the leading hydrogen technology enterprise so that we can help build a sustainable planet", and build the company's competitiveness in technology, products, services, and branding, promoting the diversification and sustainable commercial applications of hydrogen technology. Meanwhile, REFIRE Group will play the role as a hydrogen industry leader, providing support for green development in more industries, sectors, and regions, contributing to the realization of carbon peak and carbon neutrality goals in China.

ZF Group

Product: Separately excited synchronous motor

Description

The process of making the rotor form a rotating magnetic field according to the principle of electromagnetic induction is called excitation. The excitation motor changes the excitation magnetic field by changing the excitation coil current, and the magnetic field strength is large and controllable. Compared with asynchronous motors and permanent magnet synchronous motors, the torque of the excitation motor can be adjusted within a certain range to enhance output control. And it has the characteristics of high efficiency, low noise, balanced heat conduction, and stable operation. In addition, the current required by the excitation motor is small, the electromagnetic arrangement is more regular, and the service life is longer. ZF always focus on leading the development of E-Drive system in New energy field. Base on the maturing Hair Pin technology, ZF developed a new generation SESM named i²SM which can be the best solution for the high cost, low life and sustainable development. ZF also start a SESM mass-produced in China at the beginning of this year.

Unique advantages

1) low installation space required, Inductive exciter within rotor shaft, higher volumetric power density, full fit the layout requirements of different powertrains

2) Lower unit cost under the same peak power

3) High power density: the cycle efficiency of high-speed road conditions is nearly 15% higher than traditional PSM

4) Manufacturing platform Sharing: induction motor and PMSM share the production line

5) Non-touch carbon brush design: abrasion avoid

6) In order to meet the sustainability of materials for new energy vehicles, optimize the raw material selection and structure for E-motors.

Application

ZF has launched the two plants in Shenyang and Hangzhou and the E-mobility global core R&D center located in Songjiang, Shanghai. ZF provides customer with the development and manufacture of various types of E-motors, such as ASM, PSM, and SESM for 400V and 800V model. Except the world's leading Hair Pin technology, ZF still focuses on the new technology development, such as electric excitation, wave winding, oil cooling in slot, near-slot oil cooling, wave winding and product localization. ZF also provides the customer with products of the various performance levels and cost.

Prospect

ZF believes advanced technology, sustainable development, local R&D and manufacturing will surely become the trend of the E-mobility industry. As the Chinese market becomes increasingly important in the global automotive industry, ZF will still be“in China, for China”, and is willing to work together with partners to meet the opportunities and challenges from the new energy vehicle market.

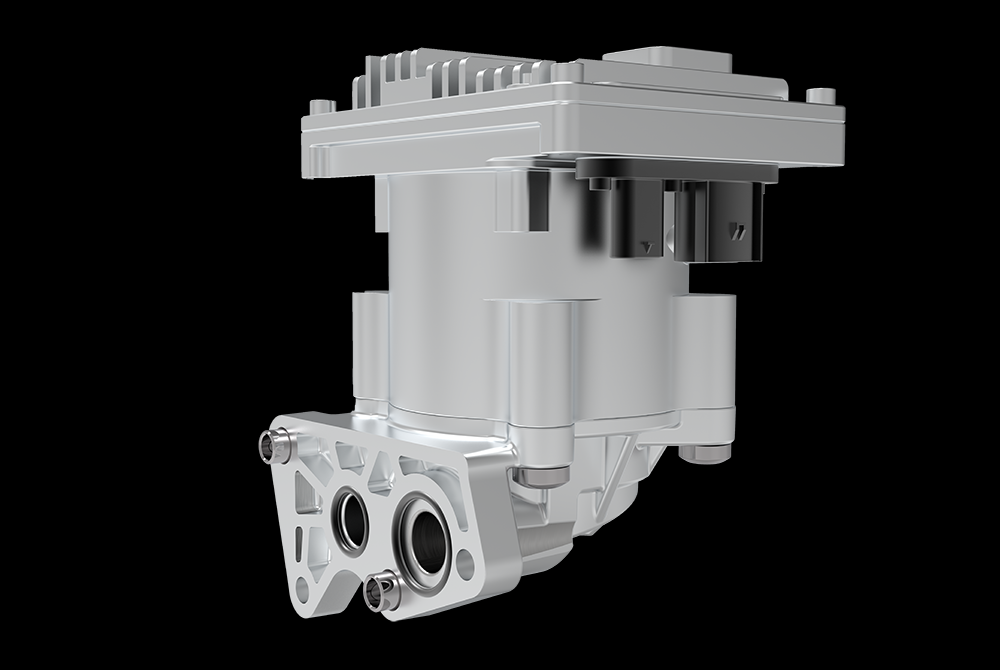

G-eDrive Tech

Product: Electronic lubrication pump

Description

The electronic lubrication pump is generally used in the Powertrain, reducer and oil cooled motor of new energy vehicles to provide the required lubrication flow according to the lubrication demand of the power transmission system. This series of products adopts an integrated design that combines the motor, controller, and mechanical pump head. It features a compact structure, high efficiency, excellent low-temperature starting performance, and a lubrication flow rate of up to 40L/min or more. It is capable of meeting the usage requirements of the majority of commercial vehicle customers.

Unique advantages

High integration high efficiency high reliability Wide temperature range Excellent NVH performance

Application

Cooling and lubrication scenarios of new energy commercial vehicle Powertrain, reducer and oil cooled motor

Prospect

With the accelerated penetration of new energy in commercial vehicles, the improvement of motor power, and the corresponding increase in cooling and lubrication efficiency, the oil cooling of driving motors has become an industry consensus. At the same time, the low efficiency of gear oil stirring lubrication and cooling in the transmission mechanism of commercial vehicles under low speed, heavy load, reverse and other working conditions, which leads to the risk of power transmission system failure, will also strengthen the rigid demand for electronic oil pumps, This field will stimulate a vast market space with the process of new energy utilization of commercial vehicles.

Viridi Energy Mobility Technology Co,. Ltd.

Product: High-efficiency and low-noise silicon carbide electric drive system

Description

VREMT's full-stack self-developed new generation high-efficiency and low-noise silicon carbide electric drive system is developed on the basis of a highly integrated three-in-one, safe and reliable parallel-axis platform solution integrating the motor, reducer and electric control unit, which uses a third-generation 8-layer Hair-Pin high PDIV flat copper wire water-cooled permanent magnet synchronous motor, one-piece high-load high-efficiency reducer, and high-efficiency and high-power density SiC electric control unit, with the total peak efficiency > 95.2%, WLTC comprehensive efficiency = 91.8%, and range improvement by more than 5%.

Unique advantages

Use of the third generation power semiconductor silicon carbide technology and permanent magnet synchronous flat wire technology to support high-power high-torque output and higher power torque density.Use of new material technology and software strategies (intelligent PWM control/optimal control of water flow) to enhance system efficiency, save power and improve the vehicle endurance.Use of optimized electromagnetic scheme, gear trimming and software strategies (active noise reduction: harmonic injection, variable carrier frequency technology) to reduce audible noise and improve riding comfort.Use of smoothness control and DTCS function to increase the torque response speed to achieve fast body stabilization and enhance driving comfort.Use of temperature management strategy and background data analysis to monitor the system health status in real time and ensure the safety of users.

Application

The 200kW high-efficiency and low-noise silicon carbide electric drive system is mainly applied in new energy vehicles, including passenger cars, commercial vehicles, trucks, etc. The system has been mass-produced in June 2022 and is equipped with ZEEKER, Smart and other brands. Up to now, more than 38,000 units have been delivered, and will be equipped with Volvo, Lynk & Co, Galaxy, Geely commercial vehicles and many other models in mass production in 2023 and 2024.

Prospect

SiC power device for electric drive system can reduce the size of motor controller with lower energy loss and battery loss and longer range, and thus can reduce the overall vehicle cost and enhance the efficiency of the system in the conditions of urban traffic, large battery capacity and low voltage. Since Tesla switched to SiC controller in 2018, many new energy vehicle enterprises and component enterprises in the world have laid out the development of SiC electric drive system. With the application of SiC in the field of new energy vehicles and the reduction of SiC cost, the penetration of SiC in the field of vehicles will become higher and higher in the future.

Shanghai Thermalnology System Co., Ltd.

Product: High voltage coolant heater with 800V thick film

Description

The 800V thick film coolant heater apply to new energy vehicles. It can not only meet the heating requirement of the passenger cabin, but also the vehicle battery pack. The heater adopts thick film heating plate technology solution. With a rated power of 10Kw. Higher heating power density. More compact structure. Heat exchange efficiency is higher than 97%. It can output full power over wide voltage range. With optional control methods such as CAN, LIN, or PWM. Complete hardware and software protection functions.

Unique advantages

1) The thick film heating element using stainless steel, has faster heating speed and higher heating power density.

2) High efficiency heat exchanger structure, so the heat exchange efficiency is higher than 97%, which is more energy-efficient, meanwhile reduce the impact of its own heat damage meanwhile.

3) In wide working voltage range, it can meet a heating power output of 10kW.

4) Equipped with power control mode or temperature control mode.

5) Complete software and hardware protection ensures reliable and long-term operation in different environments and working conditions.

6) Superior electromagnetic compatibility (EMC).

7) Functional safety level requirements, in line with ISO26262 ASIL-B requirements.

Application

By connecting the coolant heaters in series/parallel in the coolant circuit of new energy vehicles. It can simultaneously meet the functional and performance requirements of heating the passenger cabin. Defrosting and defogging the windows. Heating the vehicle battery pack. The structure is compact and convenient for layout on the vehicle.

Prospect

With the development trend of the 800V voltage platform for new energy vehicles. This thick film coolant heater can be suitable for the high voltage needs of the vehicle. 2. This high-power thick film coolant heater can be used to replace multiple low-power PTC coolant heaters. Achieving centralized use of heat sources with excellent cost-effectiveness advantages.

APTIV PLC

Product: Direct Contact Technology (DCT) portfolio

Description

Scalable, modular, flexible, adaptable connection systems for the demanding life needs of EV connections

Unique advantages

Industry leading power density/package size with scalability for various power needs; Designed for harness processing, manufacturing simplicity, and enable automation; Robust terminal design with 100x life over

conventional copper alloy terminals; Maximum flexibility for device supplier header integration; Direct Mate Technology optimizes device interface

Application

EV

Prospect

As EV market is booming, DCT will get very good application in the future.

Shanghai EVBG Drive Co., Ltd.

Product: High efficiency GaN 3-in-1 motor inverter

Description

1) Working voltage range: 240-420VDC

2) Peak power: 35kW

3) Peak current: 165Arms

4) peak efficiency: 99.34%

5) high power density, excellent NVH performance

Unique advantages

1) high power density: the power unit adopts four GaN devices in parallel design, compact structure and small volume;

2) high efficiency: the maximum efficiency of the controller reaches 99.34%, and the efficiency MAP greater than 90% accounts for 93.58%;

3) low cost: efficiency and SiC is equivalent, but the cost is relatively lower;

4) scalability: power device parallel design is easier to expand to different power level platforms, adapt to different needs;

Application

BEV/PHEV and other electric vehicle power system

Prospect

GaN devices have unique advantages such as higher efficiency (compared with IGBT) and lower cost (compared with SiC), and with the development of GaN technology, it is believed that the application of electric systems in the future will be more and more extensive.

Eaton (China) Investments Co., Ltd.

Product: xEV Heavy Duty 4-speed Transmission

Description

Eaton's new generation xEV heavy-duty 4-speed transmission (model EMA-26N0304A) has launched recently is a star product specially developed for the new energy commercial vehicle market, with a maximum input torque of 2600Nm, covering 22t-55t for regional transportation, urban construction, port traction, in-plant reverse short and other scenario applications.

Unique advantages

Eaton has created this product with the following four core features: "Light", "Durable", "Save" and "Smart". "Light"! Lighter weight and lighter noise. This 4-speed transmission adopts all-aluminum housing and the gear shaft is proprietary lightweight design, weighing only 192 kg, which is more than 20% lighter than similar products. Full helical gear design combined with gear shape optimization, the product NVH performance is better. "Durable"! Eaton's nearly 40 years of AMT applications and product iterations have forged its excellent quality of hardware and software. The enhanced design of EV gears and the platform application of highly reliable core components make the product B10 life is 1.6 million km under road application. "Saving"! High transmission efficiency and long oil change interval, saving money and being free from worry. The use of forced lubrication and low friction coefficient bearings makes the transmission efficiency increase by more than 1% compared with the previous generation products. At the same time, the special fully synthetic lubricant, no need for first warranty, oil change intervals up to 800,000 km under road application. "Smart"! TCU integrates slope sensor, which can sense the slope and calculate the vehicle weight intelligently, making the gear shift more intelligent and adaptable. Meanwhile, with the upcoming new generation TCU, it can realize full-function UDS diagnosis, OTA program online upgrade, ISO26262 functional safety and other functions.

Application

It can cover 22t-55t for regional transportation, urban construction, port traction, in-plant reverse short and other scenario applications.

Prospect

From the structural changes of new energy commercial vehicle sales in recent years, the share of new energy medium and heavy truck market in the overall new energy commercial vehicle sales is increasing year by year. Meanwhile, in recent years, the proportion of new energy commercial vehicles in overseas markets such as North America, Europe and Southeast Asia has also been rising year by year, and Eaton has successfully obtained orders for this new product from many overseas customers by virtue of its professional technical ability and industry reputation.

Gasgoo not only offers timely news and profound insight about China auto industry, but also help with business connection and expansion for suppliers and purchasers via multiple channels and methods. Buyer service:buyer-support@gasgoo.comSeller Service:seller-support@gasgoo.com