Gasgoo Awards 2023 receives multiple applications in intelligent chassis segment

Gasgoo, a global leading automotive industry information service platform, has kicked off the Gasgoo Awards 2023 program. For the Top 100 Players of China's New Automotive Supply Chain, the program will cover ten core segments, namely autonomous driving, smart cockpit, software, automotive chip, artificial intelligence, powertrain electrification, intelligent chassis, body and exterior & interior, low-carbon and new materials, as well as thermal management.

In intelligent chassis segment, the Gasgoo Awards 2023 have attracted multiple companies to apply for the Top 100 Players of China's New Automotive Supply Chain. Here are some details about them.

Brembo (Nanjing) Automobile Components Co., Ltd.

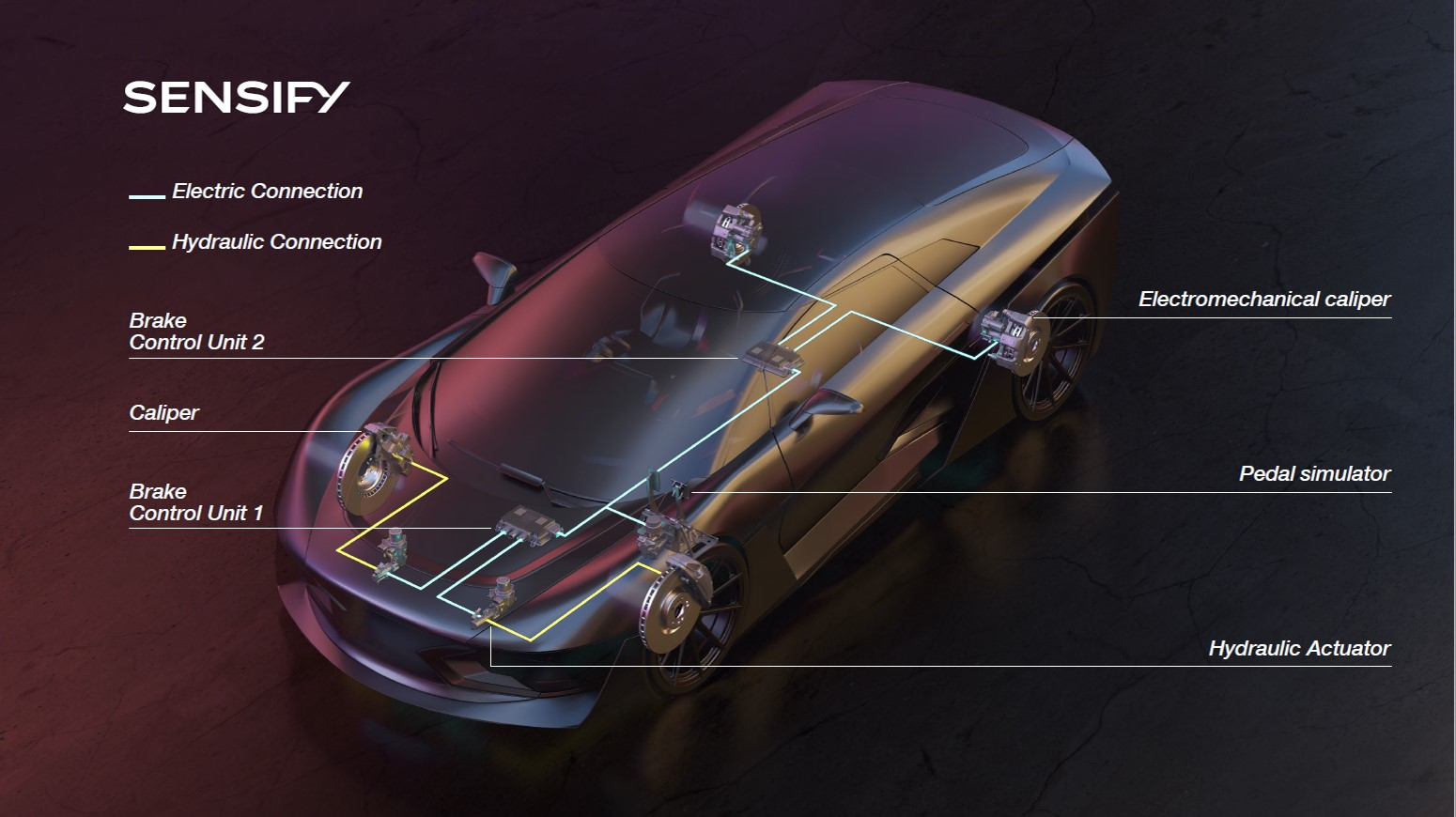

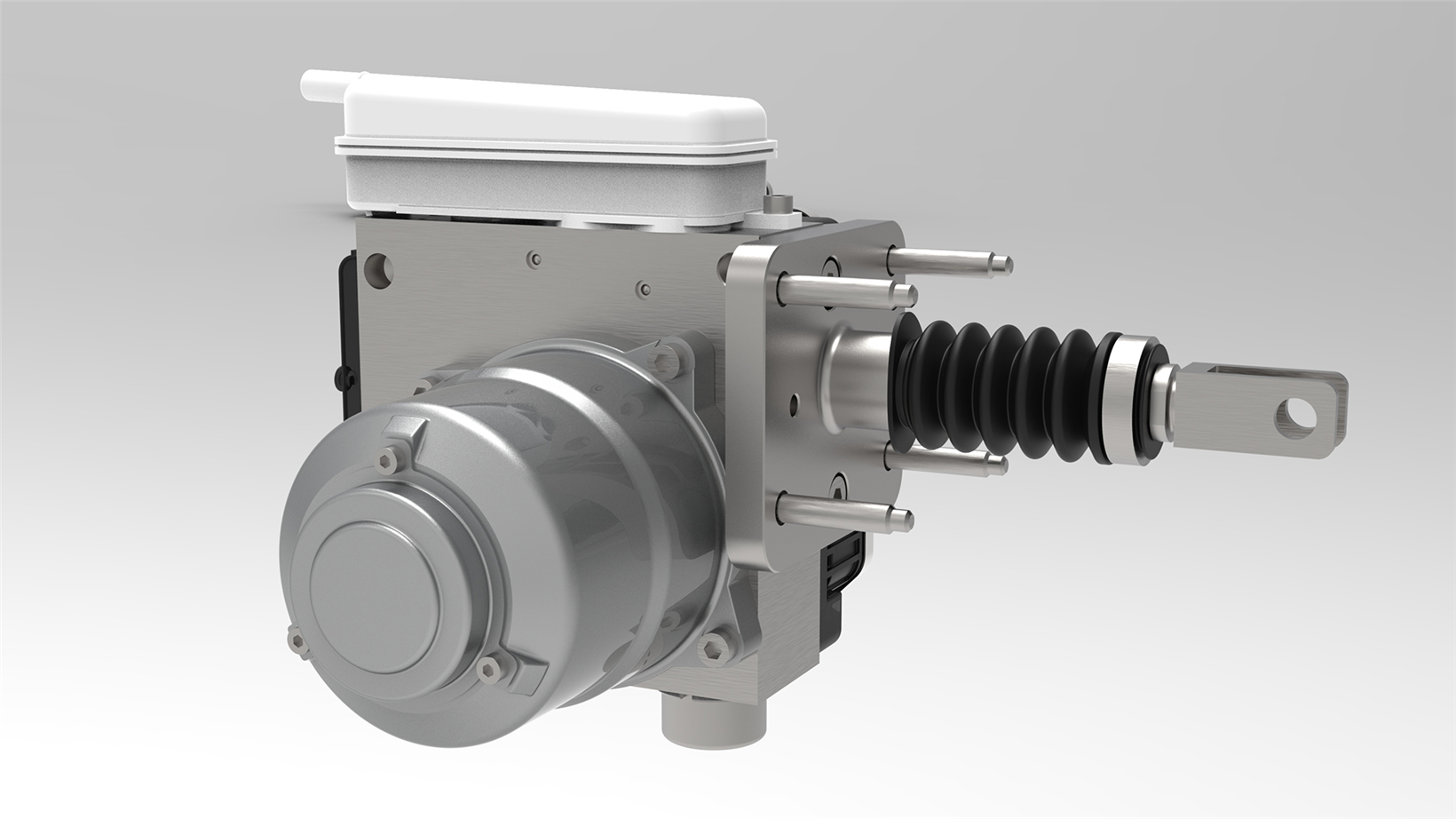

Product: SENSIFY

Description

Unveiled in October 2021, SENSIFY is a new pioneering intelligent braking system and crystallizes Brembo’s cutting-edge research results in intelligent braking systems which it has been working on for more than 10 years. SENSIFY comes from the merge of two words: SENSE that is a faculty by which a human perceives an external signal and stimulus; and SIMPLIFY which means simplicity in installing at best the product in harmony with the vehicle. SENSIFY has evolved naturally from Brembo’s heritage and know-how. It combines the design of the best braking components with the integration of a digital brain and sensors, and is an electronic braking system with independent and wheel-distributed braking actuation. SENSIFY integrates the most advanced software based on artificial intelligence with Brembo’s world-renowned brake components. It combines the current Brembo product portfolio of calipers, discs and friction materials with digital technology and artificial intelligence to create a flexible and revolutionary platform that includes software, predictive algorithms and data management to control the brake system digitally, to customize brake response to drivers’ driving style, and to improve their experience on the road. SENSIFY constantly delivers driving pleasure and total safety. It is intuitive, responsive and smooth; it delivers the driver the expected performance when needed, combined with exceptional control. SENSIFY meets the market needs for more digital, electric and intelligent passenger cars, responds to government policies for energy saving, emission reduction and environment protection in the automotive industry, and is an innovative intelligent braking system with epoch-making significance.

Unique advantages

Compared to a traditional braking system, SENSIFY is an electronic braking system with independent and wheel-distributed braking actuation which, besides the smart management of NVH calibration, controls the braking force of each wheel independently according to the driver’s needs, vehicle dynamics and traffic conditions. SENSIFY strives to deliver brand-new driver experience and enables drivers to leverage their sensitivity. With SENSIFY the braking system is no longer simply a sum of its parts but an ecosystem, where artificial intelligence and software play an active role. Data collection is leveraged to improve the driver experience and allow the system to be constantly updated, with a view to creating value added for end users. SENSIFY is also a more sustainable braking solution. Thanks to the optimized braking action on each wheel combined with the absence of drag between pads and discs, dust emissions are minimized, range is increased, and battery size is reduced. Reducing drag torque will be one of the biggest contributors to reduce CO2. Lower brake temperature due to managing 4 independent corners will lower brake dust and wear. SENSIFY is eco-friendly due to the absence of brake fluid and fewer components and parts, and avoids the complications of bleeding the system, as well as storage. By braking, you regenerate energy into the battery. With SENSIFY, the regenerative braking is always at the top level under all driving conditions. SENSIFY offers great flexibility for OEMs’ chassis design. With fewer components and no brake fluid and brake lines, this solution is cost-effective and gives more space for chassis design. It features shorter development time and easier software integration with electric vehicles and fuel vehicles, thus covering all market segments including supercars, city cars and new commercial vehicles. Besides service braking functions, SENSIFY integrates advanced vehicle control functionalities related to the braking (e.g. EBD, ABS, ESC). Two ECUs read the driver’s brake request via sensors on the brake pedal. The front ECU controls two electro-hydraulic actuators, meanwhile the rear ECU controls two electro-mechanical calipers, integrating also the electric parking brake function.

Application

SENSIFY improves the performance of vehicles of all types. This distributed system has many benefits and applies to diverse vehicles and structures. It offers possibilities for vehicle design and great flexibility for carmakers. It realizes easier integration with electric and fuel vehicle platforms, covering all market segments including supercars, city cars and even new commercial vehicles.

Prospect

SENSIFY meets the market needs for more digital, electric and intelligent passenger cars, responds to government policies for energy saving, emission reduction and environment protection in the automotive industry, and is an innovative intelligent braking system with epoch-making significance. Once applied, SENSIFY will have profound implications for:

1) The driver: • Adjusting brake response according to his/her driving style preferences since the traditional brake pedal feeling is guaranteed by a brake pedal simulator. • Greater safety and system stability, more controllable brake and vehicle posture in cornering. • Regenerative braking and energy recovery for an increased range.

2) The carmaker: • Modular configuration, shorter development time and easier software integration for vehicle platforms. • Independent control of each wheel’s braking force and smart management of NVH calibration. • No brake fluid and brake lines, more flexible chassis design, and less vehicle manufacturing costs • Integrating advanced vehicle control functionalities related to the braking (e.g. EBD, ABS, ESC), and less braking components • Prospective technologies applicable to automatic drive

3) The environment • Less drag torque, brake dust and CO2 emissions, increased life yet smaller size of battery. • No brake fluid and less environmental impact.

Bebest (Shanghai) Automotive Electronics Co., Ltd.

Product: BIBO Integrated Brake Control System(BIBC/One-Box)

Description

The core product of BIBO's self-developed full stack is the Integrated Brake Control System (BIBC), which adopts the One Box technology solution and is a highly integrated electronic braking system based on hydraulic pressure. It integrates functions such as eBooster, ABS, ESC, EPB, and supports intelligent driving. It integrates hydraulic assistance function with pressure regulation function, not only having brake assistance function, but also vehicle stability control function, and has the ability to integrate EPB control and chassis integration control. Meet the requirements of L3/L4 unmanned driving, with outstanding advantages such as high integration, high performance, high safety, and high redundancy.

Unique advantages

BIBC has significant advantages in both software and hardware: 1. High computing power, 4-core MCU, adopting a "hardware embedded" approach; 2. High security, meeting the requirements of ISO26262 Functional safety, ISO21448 expected Functional safety, and ISO/SAE21434 network security; 3. Convenient layout, smaller appearance compared to similar products, and flexible matching of vehicle installation; 4. Strong performance, TTL ≤ 150ms, braking performance improved by 30%; 5. Strong application, redundant parking brake, meeting the requirements for vehicle models below 4.5T; 6. Strong scalability, supporting customized development of customer functions, supporting OTA, and meeting the requirements of rapid software iteration; 7. Low cost, with a 30% reduction in the cost of single vehicle wire controlled braking. BIBC can be combined with the brake redundancy module BRBM to form a high redundancy One-Box scheme, where BIBC serves as the main brake and BRBM serves as the redundant braking system, achieving: 1. Multiple redundancy such as service brake control, parking brake control, stability control, software cross monitoring, hardware redundancy configuration, etc; 2. Even in the event of BIBC failure, it has a backup braking force of over 1g and can achieve seamless switching of mechanical and hydraulic braking; 3. The development service Software architecture can realize flexible software transplantation, customized customer development, and convenient docking to achieve XYZ integration control.

Application

It can be applied to passenger cars, light passenger cars, light trucks, pickup trucks, unmanned vehicles, special vehicles, and other vehicle models.

Prospect

At present, the penetration rate of electrification and intelligence in automobiles is increasing in a double helix, and users' demand for safety, comfort, and intelligent experiences is increasing day by day. The development model, technical strength, and product planning of BIBO are in line with market development trends, meeting the development needs of integrated, lightweight, and high reliability of intelligent vehicle braking systems. BIBO will break the international monopoly, meet the rigid needs of Alternative fuel vehicle, and promote the development of electric and intelligent vehicles. Leading the technological innovation of chassis products, supporting the landing of L4/L5 autonomous driving, deeply cooperating with mainstream domestic vehicle manufacturers, jointly developing advanced autonomous driving by wire chassis solutions, and defining a new generation of intelligent travel tools.

Shanghai Leekr Technology Co., Ltd.

Product: Integrated Hydraulic Brake (IHB-LK®)

Description

Leekr IHB-LK realizes brake pedal decoupling by controlling electromagnetic valves to simulate brake pedal feeling, which fully retrieves the braking energy by driving electric motor. Besides, it innovatively overcomes the design flaws of idle stroke in existing semi-decoupled mechanical solutions, ensuring drivers immediately brake under any circumstances. Leekr IHB-LK is one of the few frontiers who can massly produce the brake-by-wire One-box solutions in China so far.

Unique advantages

1) High system integration

2) Fully decoupled hydraulic system and adjustable styles of the pedal feeling

3) High dynamic response

4) Coordinated Energy Regeneration Brake System (CRBS)

5) New system architecture design, and safety redundancy of the system failure mode

Application

Autonomous driveing, Electric Vehicles, Fuel Vehicles

Prospect

The relevant data show that the penetration rate of new energy passenger cars in China reached 27.6% in 2022, 12.6 percentage points higher than in 2021. From 2023 onwards, the domestic passenger car brake-by-wire market will gradually explode, and by 2025, the overall market size of domestic passenger car brake-by-wire products will exceed 40 billion yuan, and the overall brake-by-wire chassis market size will reach 100 billion yuan.

KH Automotive Technologies Co., Ltd.

Product: Electronically Controlled Suspension system

Description

The electronically controlled suspension system of passenger car generally includes air spring, variable damper, height sensor, acceleration sensor, controller, air supply unit assy, reservoir, pipeline and other components. According to the height sensor, body acceleration sensor and vehicle status signal, the controller can adjust the soft and hard suspension and body height under the premise of meeting the safety requirements, so as to improve the ride comfort and operating stability of the vehicle. The single and dual cavity stiffness of the dual chamber air spring can be adjusted, which can further improve the vehicle comfort and handling.

Unique advantages

KHAT is a technology-based enterprise engaged in the development, production and supply of passenger car Electronically Controlled Suspension System and core components, with the complete capability of the whole process of matching development, test verification, calibration, production and supply of Electronically Controlled Suspension System. The key components that KHAT can provide include: system controller hardware /software, (single/dual chamber) air spring assy, ASU, etc. KHAT has a comprehensive air suspension development capability from key components to system level, from ride performance to life reliability, including air spring research and model matching the dynamic mechanics performances, mechanical design, a variety of manufacturing processes, air pressure system design, special test equipment development and other knowledge areas. Meanwhile, the air spring compression and assembly line are the core accumulated by KH for many years, in which the implanted core algorithm has certain uniqueness and strong competitiveness. In terms of electronically controlled suspension systems, KH adheres to positive research and development and has a number of intellectual properties. The electronically controlled suspension system of KHAT for passenger cars is independently developed using the V Process common in the automotive industry, and can provide a full set of customized solutions from model planning, function definition, matching design, test verification, calibration until SOP. In the matter of air spring assy and ASU, KH has assembly and some parts of the process development capabilities, and key processes are self-sufficient. The quality of our own assembly products is strictly implemented in accordance with the DV&PV test standards, and we are fully able to deliver qualified products in time according to the needs of customers.

Application

With the development and growth of the domestic new energy vehicle industry and the improvement of model positioning, the characteristics of air suspension based on chassis lifting and high comfort have brought convenience(on/off the car, trunk loading), higher quality(isolate high-frequency vibration, automatic leveling of low-frequency offset deviation with load changes), battery protection(isolate high-frequency vibration, passability), the advantages such as increased mileage(high-speed reduction of chassis/wind resistance) have become an important configuration for OEMs to actively promote. At present, KHAT supplies Air Suspension system and Air Spring assy for L9 and L7 of Li Auto, VOYAH FREE, VOYAH Dreamer, VOYAH and 009ME of ZEEKR. By June 2023, KHAT has completed the delivery of 160,000sets. KHAT obtained about 40 models of 14 OEM’s nominations such as VOYAH, Li Auto, BYD, ZEEKR, LYNK&CO, CHANGAN Auto, AVATR, AION, CHERY and so on.

Prospect

KHAT has been funded by well-known institutions such as China Venture Capital, CRRC Guochuang and Source Code Capital, as well as national high-tech enterprise, provincial R&D center certification and is a national Specialized and New "Little Giant" firm. With the popularity and application of air suspension in new energy models, the delivery volume of KH's air suspensions continue to rise rapidly, and the company is in the fast lane of development and growth. KHAT will always uphold the mission of "Popularize Enjoyable and Safe Driving", adhere to providing cost-effective products and services for the domestic automotive industry, KH is willing to work together with OEMs and automotive parts enterprises to create a win-win future.

Shanghai Trugotech Automotive Technology Co., Ltd.

Product: EHBI (Electric Hydraulic Booster-Integrated)

Description

EHBI is a decoupled electro-hydraulic brake system , which can realize braking-by-wire through electric motors and solenoid valves. As a hydraulically decoupled Onebox product, EHBI achieved an extremely high degree of integration through the concentration of ESC and EHB functions, which can provide good pedal feeling and excellent emergency braking capability.

Unique advantages

Decoupled Onebox :Designed for vehicle electrification and intelligence intellectualization;VMC: First Onebox integrated whole functions of VMC;Multifunctional: Integrated various intelligent functions;Smart Driving Level L2+/L3/L4/L5

Application

intelligent vehicle and EV

Prospect

With an annual capacity of 2 million and annual sales over 1 billion RMB

Suzhou Gates Electronics Technology Co., Ltd.

Product: Intelligent Chassis Domain Controller

Description

Gates Electronic Intelligent Chassis Domain Controller is based on the mature experience and project accumulation of Gates Electronic Online Steering, active suspension, brake by wire and other single node aspects, integrating functional safety, information safety and other safety considerations, covering body height control, body stiffness control, damping continuously adjustable damping control, rear wheel steering control, steering column position control and other functions, and combining with intelligent actuators, provide a chassis domain controller for high computing power platforms. We can provide customers with a all-in-one solution that integrates vehicle steering, suspension, braking, and other control functions in the X, Y, and Z directions. In terms of supply chain security, Gates Electronic Intelligent Chassis Domain Controller can also simultaneously provide localization alternatives to ensure supply chain security.

Unique advantages

Electrical redundancy: a.Dual power supply system,b.Degraded processing mode . Communication redundancy: a.Dual CAN communication mode, b.Dual MCU response verification. Hardware redundancy: a.Redundant backup of external processing chips, b.Redundant design of actuators/sensors. Software redundancy: Design of Redundant Monitoring Strategy.

Application

It is used for steering by wire, braking by wire, Active suspension and other single node systems to control direction, and can be used in the field of chassis domain control combined with multi node linkage simultaneously.

Prospect

Applied to skateboard chassis and unmanned driving field.

Anhui Zhongding Sealing Parts Co. Ltd.

Product: Air suspension system, chassis lightweight system

Description

1) Air suspension system: Automobile suspension system is the entire support system consisting of a spring and shock absorber between the body and the tire, it is the connecting device between the body and the wheel,it can transfer the forces and moments acting between the wheel and the frame, cushion the impact of uneven road surface to the frame or body,attenuating the resulting vibration and ensure the smooth running of the car.According to the difference of road environment and the signal of the distance between the car and sensor, the driving computer will determine the height of the body, and then control the air compressor and exhaust valve, so that the spring automatically compressed or extended, thereby reducing or raising the chassis clearance from the ground, in order to increase the high-speed body stability or the passing of complex road conditions. The air suspension system gives a car both the comfort of a car and the handling performance of an off-road vehicle. Air suspension systems include air compressors, control units, multi-system sensors, air springs, and more.

2) Lightweight chassis system: The product is composed of control arm,ball join assembly and its support,front bushing and its support,rear bushing and its support and damper bushing.It is used to connect the wheel,subframe and damper, it can transfer the load and control the wheel travel track. It has an important impact on the safety,comfort and handling of the car.

Unique advantages

1) Air control unit:Working pressure up to 21bar, it meets the requirements of air suspension pressure and supports more aerodynamic function at the same time.The service life reaches 1000hours,meeting the use of vehicle service life;1000 hours air control unit service life can guarantee 12000 times of air storage tank inflation,twice per day,it is expected to be 6000 days.The use of Ndfeb magnetic steel, magnetic is three times that of ferrite;The motor shell is sealed, there is no high pressure gas inside the motor chamber, and the surface of the compression chamber is provided with anti-rust coating to prevent internal rust; Anti-icing design, desiccant performance support dew point reduction of 40K, to prevent freezing in low temperature environment.

2) Lightweight chassis system:Control arm,rear bushing support and ball pin support are designed with forged aluminum, which has high material strength and low density, greatly reducing the unsprung quality of the vehicle, improving vehicle handling and comfort, and improving fuel economy and driving range of new energy vehicles;Ball head joint assembly adopts the upper riveting structure, which greatly improves the axial bearing capacity and increases vehicle safety compared with the traditional lower riveting structure products. The rear bushing adopts hydraulic bushing to improve vehicle comfort; The front overhang bearing arm and guide arm are combined to reduce weight and cost and save space.

Application

1) Air suspension system: Lift and lower the body of the passenger car, provide a more comfortable driving experience for drivers and passengers. When driving at high speed on a horizontal road surface, the body becomes lower and the spring becomes softer, improve driving comfort. When driving on the uneven road surface, the body becomes higher, the spring stiffens, eliminates bumps, improves passability and handling stability. Prevent acceleration, deceleration and steering, longitudinal elevation and planting head and lateral tilt, keep the optical axis of the headlamp light unchanged to improve the safety of driving. It can also realize comfortable and convenient value-added functions such as welcome mode and loading mode through active suspension height control.

2) Lightweight chassis system: automotive lightweight has formed a broad consensus in the automotive manufacturing industry, the lightweight of the chassis plays a pivotal role in the performance of the vehicle, aluminum alloy control arm assembly products and other lightweight chassis products are of high value, but also the core components of operational stability and comfort. This type of product can be applied to the front suspension of various types of vehicles, especially suitable for the compact suspension space, fuel economy and endurance requirements of high models.

Prospect

1) Air suspension system: With the advent of the era of new energy vehicles, the appeal of new energy vehicles intelligent, while chassis protection air suspension system is no longer the exclusive high-end models, because the new energy vehicle chassis system stability requirements are much higher than pure fuel vehicles, air suspension system has gradually become the mainstream configuration of the new energy vehicle platform. AMK Germany, as a high-end supplier of air suspension system, is one of the top three leaders in the industry. Since entering the field of air suspension system business in the 1990s, it has continuously improved the product assembly technology, and has been deeply engaged in the industry for more than 20 years, supporting the world's leading vehicle manufacturers such as Jaguar, Land Rover, Volvo, Audi, Benz, BMW etc. The domestic air suspension market is in its infancy, and AMK China has been accelerating the improvement of the performance and cost optimization of the air suspension system supply chain in the Chinese passenger car market. AMK continued to develop steadily around the strategic goals of "localization promotion, technology iteration and upgrading, and industrial strengthening and completing". AMK China continues to promote the implementation of other self-produced hardware projects while launching air supply unit product assembly and production lines in succession to increase the proportion of self-produced hardware. Business of AMK China has made breakthrough progress, and it has also obtained orders from many domestic new emerging manufacturers and leading vehicle manufacturers. Up to now, AMK China has received orders with a total output value of 7.314 billion RMB, and it is expected to get more orders in the future, especially new energy vehicle orders.

2) Lightweight chassis system: Due to the needs of environmental protection and energy saving, the lightweight of automobiles has become the trend of automobile development in the world. The lightweight of automobiles is not only suitable for traditional fuel vehicles, for new energy electric vehicles, it is also very important to reduce body weight and achieve vehicle lightweight, because it is related to the main battery life of new energy vehicles. In recent years, the company has been vigorously developing chassis lightweight system assembly products, and the forged aluminum control arm assembly project has made breakthrough progress. At the same time, its subsidiary Sichuan Wangjin Company, whose core technology is the ball joint assembly product, is the core safety component and performance component of the chassis system. It has the world's leading technology and has a very high technical threshold. With the continuous advancement of the company's lightweight chassis system assembly business, it has obtained orders from many traditional OEMs such as Mercedes-Benz, Changan, GAC, BYD, etc. At the same time, it has made breakthroughs in the business of leading new energy enterprises and obtained relevant orders.

Gasgoo not only offers timely news and profound insight about China auto industry, but also help with business connection and expansion for suppliers and purchasers via multiple channels and methods. Buyer service:buyer-support@gasgoo.comSeller Service:seller-support@gasgoo.com