Gasgoo Awards 2023 receives many applications from thermal management segment

Gasgoo, a global leading automotive industry information service platform, has kicked off the Gasgoo Awards 2023 program. For the Top 100 Players of China's New Automotive Supply Chain, the program will cover ten core segments, namely autonomous driving, smart cockpit, software, automotive chip, artificial intelligence, powertrain electrification, intelligent chassis, body and exterior & interior, low-carbon new materials, as well as thermal management.

In the thermal management segment, the Gasgoo Awards 2023 have attracted a number of companies to apply for the Top 100 Players of China's New Automotive Supply Chain. Here are some details about them.

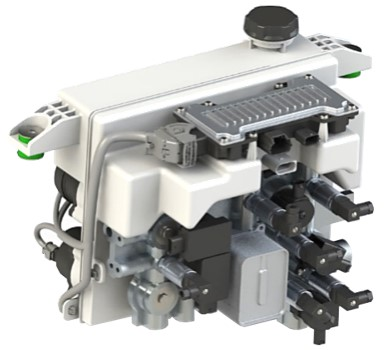

Hilite Automotive System (Changshu) Co., Ltd.

Product: Integrated thermal management module for electric vehicles with smart controller

Description

Hilite's integrated thermal management module solution includes: refrigerant side integrated valve Island & integrated module, coolant side integrated module, large integrated module for refrigerant side and coolant side, and the thermal management integrated module controller. It effectively saves costs and layout space. By adjusting the working mode of the thermal management integrated module, precise control of the overall vehicle energy flow can be achieved, further providing safer, more comfortable, and multifunctional services for new energy vehicles.

Unique advantages

Hilite TMS offers a one-stop solution, with refrigerant valves featuring low leakage, high durability, and stability. The multi-way water valve, as an innovative product, adopts a face-sealed design, boasting small size, light weight, low internal leakage, and superior performance.

Application

Hilite's integrated thermal management module finds wide applications in pure electric or hybrid vehicles for various thermal management tasks. This includes water cooling or direct cooling for batteries, water cooling and waste heat recovery for electric drives, cabin refrigeration, and heat pump heating. The integrated module combines most thermal management components within limited space, reducing costs, decreasing weight, and enhancing heat transfer efficiency. The smart controller also supports over-the-air (OTA) upgrades. The thermal management integrated module enables adaptive and complex thermal management for electric vehicles, reducing overall vehicle costs, increasing driving range, and simultaneously ensuring passenger comfort and safety.

Prospect

Hilite adheres to the principle of “In China, For China” and will further expand our sustainable business in China through upgraded NEV R&D center, factory, and software capabilities. In March 2023, Hilite China successfully passed the ASPICE CL2 certification, indicating a significant advancement in their software development process, providing a robust assurance of high-quality products. Hilite is committed to continuous investment in software applications and aims to move towards even higher standards in the future. Regarding company strategy, Hilite aims to become a key participant in the core valve products of thermal management in the short to medium term. In the long term, building on our foundation in thermal management core valve products, we will strive to become a major participant in thermal management module products.

Spintrol Electronic Technology (Shanghai) Co., Ltd.

Product: AUTO Highly integrated motor drive chip (SOC)

Description

The SPD1179 device from Spintrol is a highly integrated system-on-chip (SoC) microcontroller. The SPD1179/SPD1176 incorporates a 32-bit ARM® Cortex-M4F high-performance processor with a software-programmable clock rate up to 100 MHz, 32 KB SRAM, 128 KB embedded flash with up to 1 KB EEPROM emulated by extra 12 KB flash, and an extensive range of enhanced I/Os and peripherals. The device offers a 13-bit ADC, one differential PGA and one single-ended PGA, four enhanced PWMs, three general-purpose 32-bit timers, as well as standard and advanced communication interface: two UARTs with LIN support, two SPIs, one I2C and one CAN.

Unique advantages

Highly integrated, high reliability, filling the gap in this application field in China

Application

BLDC/BDC, sunroof controller, automobile compressor, wiper controller, seat controller, thermal management, water pump, oil pump, cooling fan, and so on

Prospect

Expert in motion control, and set up the best in the industry

onsemi

Description

onsemi's Top cool MOSFET simplifies design and reduces cost for compact power solutions, which assist designers in challenging automotive applications, especially within motor control and DC/DC conversion. Housed in a TCPAK57 package measuring just 5mm x 7mm, the new Top Cool devices feature a 16.5mm2 thermal pad on the top side. This allows heat to be dissipated directly into a heatsink rather than via a typical printed circuit board (PCB). By enabling the use of both sides of the PCB and decreasing the amount of heat going into it, the TCPAK57 provides increased power density. Improved reliability of the new design adds to an overall extended system lifetime.The devices deliver the electrical efficiency required in high power applications with RDS(ON) values as low as 1mΩ. Additionally, the gate charge (Qg) is low (65 nC), reducing losses in high-speed switching applications.TCPAK57 initial portfolio includes 40V, 60V and 80V. All devices are capable of operating at junction temperatures (Tj) of 175°C and are AEC-Q101 qualified and PPAP capable. This, along with their gull wings that allows inspection of solder joints and superior board level reliability, makes them ideally suited to demanding automotive applications.

Unique advantages

Conventionally, cooling discrete power devices such as MOSFETs involved passing thermal energy through the PCB to a heatsink. However, this is not an ideal thermal path and, consequently, device performance was hampered. Top cool MOSFET moves the thermal pad to the top, thereby allowing a heatsink to be bonded directly to the device. Not only does this improve cooling of the MOSFET, it also allows the underside of the PCB to be used for component placement, thereby increasing power density in critical applications such as automotive.

Application

High/medium power motor controls such as electric power steering and oil pumps.

Prospect

Cooling is one of the greatest challenges in high power design and successfully addressing it is the key enabler to reducing size and weight, which is critical in modern automotive design. With more and more electronic components in the car, it also poses a challenge to heat dissipation, especially when many components in the car are operating at high power, so the automotive industry is constantly looking for ways to improve heat dissipation. For system designers, the higher the energy efficiency, the less waste heat is generated. In terms of thermal management, this means that fewer heat sinks or heat sinks can be completely removed, reducing the size, weight and cost of the solution. onsemi's Top Cool MOSFET provides excellent electrical efficiency and has eliminated the PCB from the thermal path, significantly simplifying the design while reducing size and cost.

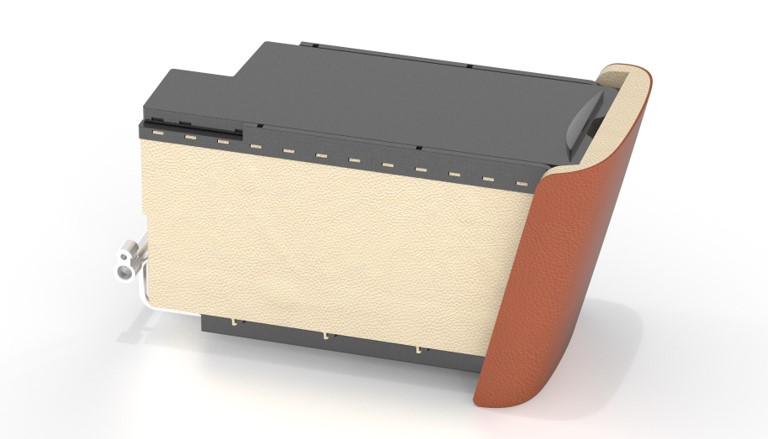

Thermalnology (Wuhan) Hi-Tech Co., Ltd.

Product: Integrated Cooling Storage Vehicle Refrigerator

Description

The design scheme of the Vehicle Integrated Cold Storage Refrigerator conforms to the trend of integrated vehicle components, achieving cost savings and significantly improving the cooling capacity of the car refrigerator. It provides customers with high-performance and low-cost car refrigerator solutions. The Vehicle Integrated Cold Storage Refrigerator is the first to adopt a cold storage function and is simultaneously integrated into the parallel branch system of the vehicle's thermal management system, eliminating the need for independent compressors and condensers, achieving significant cost savings. This refrigerator using the compressor and condenser of the vehicle's thermal management system, utilizing the powerful cooling capacity of the vehicle's refrigeration system to achieve strong performance of rapid cooling with large cooling capacity. At the same time, cold storage materials can achieve long-term operation of the refrigerator without starting the refrigeration compressor.

Unique advantages

1) Rapid cooling It can utilize the powerful refrigeration capacity of the entire vehicle refrigeration system to achieve rapid cooling.

2) Low noise and no vibration No need for independent high noise components such as compressors and condenser fans; Sound pressure level<30dB. 3) High proportion of storage space No need for independent compressors, condensers, and condenser fans, saving a lot of space.

4) No waste heat emissions to the passenger compartment Utilizing the vehicle condenser for heat dissipation, waste heat is discharged outside the vehicle through the vehicle condenser, and there is no waste heat emitted inside the passenger compartment.

5) Low starting frequency of compressor The stored cold capacity can be used to maintain the temperature of the refrigerator. There is no need to start the compressor, which can significantly reduce the frequency of compressor startup.

6) The refrigerator can work normally after parking After parking, the refrigerator can operate normally without turning on the compressor.

7) High temperature control accuracy. The temperature of the refrigerator can be maintained by utilizing the cold storage capacity stored in the cold storage module, without being affected by fluctuations in the vehicle's evaporative pressure.

Application

1) Layout location: Located in the passenger compartment, front compartment storage room, or trunk of the entire vehicle.

2) The temperature inside the refrigerator can be adjusted to achieve freezing and refrigeration functions, and the temperature of the storage room can be accurately controlled according to customer settings.

3) During daily use, relying on strong cooling capacity, it can achieve rapid cooling, and cold drinks can be quickly consumed in the scorching summer.

4) When going out for an outing, relying on the large storage space, you can carry a large amount of food or drinks.

5) In cold winter, switch the heating function to drink warm hot drinks anytime and anywhere.

6) When driving long-distance cars, the large storage space provides a strong storage capacity for logistics support materials.

Prospect

1) In line with the trend of integrated automotive components, reduces the number and cost of components, and has advantages in product cost competitiveness.

2) It has strong cooling capacity and large storage space, with competitive performance advantages.

3) The characteristics of low-cost and high-performance products provide favorable conditions for the large-scale popularization of car refrigerators in automobiles.

Kelvin New Energy Technology Wuxi Co., Ltd.

Product: 8KW Energy storage battery thermal management

Description

Voltage range:230V/460V±20%, 50/60Hz general Operating range: -30°C-60°C refrigeration, -40°C-80°C communication , Standard communication: CAN2.0/RS-485 , Refrigerant R134a (compatible with R1234yf), Rated working conditions: inlet air temperature 45 °C, coolant outlet temperature 18 °C, Parts IP67 protection, IPX6 waterproof, The unit is C5M level anti-corrosion , Altitude 0-4000m, UL/CE certification.

Unique advantages

1) High efficiency of the whole machine: it adopts various technologies such as full natural cooling technology, hybrid refrigeration technology, optimal control strategy of free cooling and compressor refrigeration, and control strategy of optimizing the optimal efficiency range of compressor; At the ambient temperature in the transition season, the unit can operate in the hybrid refrigeration operation mode of compressor refrigeration and free cooling to meet the cooling load demand; At the ambient temperature below -5°C, the unit can operate in the all-free cooling operation mode to meet the cooling load demand; The adoption of multiple new technologies has greatly optimized the operation efficiency of the whole machine, COP and the comprehensive operation efficiency IPLV of the whole machine.

2) High reliability design: the refrigerant direct cooling technology is used to cool the compressor drive, and efficient cooling can ensure that the whole machine runs at an ambient temperature of 55°C without unloading and driving without capacity reduction; The compressor is designed with gas separation to avoid the compressor suction and liquid, and ensure the stable and reliable operation of the compressor; The electrical parts are designed with IP67 protection level; The frame of the whole machine meets the requirements of 2440h neutral salt spray test; The O-ring sealing method and the refrigerant pipeline pressure plate connection method with strict compression calculation are adopted, which greatly reduces the risk of unit leakage.

3) Strict machine verification test: EMC tests in accordance with IEC standards, including electromagnetic radiation disturbance, electrostatic discharge immunity, surge immunity, RF electromagnetic field radiation immunity, RF field induction conducted disturbance immunity, etc., the whole machine can be better applied to various energy storage systems and safe operation; The protection level test, salt spray test, electrical function test, electrical safety test, electrical circuit protection test, mechanical safety test and MAP performance test of the whole machine and full working conditions operation are comprehensive and rigorous test processes, so that the reliability of the product is fully verified.

4) Lightweight design: the design optimization of the overall frame structure of aviation aluminum sheet metal is used to reduce the amount of materials under the premise of increasing structural strength and frame rigidity.

5) Intelligent control system design: optimize the efficiency of the operation mode selection control logic, compressor frequency conversion speed regulation and refrigeration system pressure coupling efficient control logic, unit refrigerant circuit and coolant circuit based on temperature, pressure, current, oil supply pressure difference comprehensive safety control protection strategy and PID control logic, so that the operation of the whole machine in the energy storage system is more reliable and efficient.

Application

Electric vehicle charging infrastructure energy storage system, power grid and power plant energy storage system, industrial energy storage system, transmission and distribution energy storage system, residential energy storage system, renewable energy storage system.

Prospect

Under the background of global "carbon neutrality", new renewable energy is favored, and the installed capacity of wind and solar is increasing, because wind and solar power generation has indirectness and volatility, energy storage has become the main solution for abandoning wind and light, and it is currently applied on the power generation side, the power grid side and the user side. During the 14th Five-Year Plan period, the National Energy Administration put forward a development target of no less than 30GW in the "Guiding Opinions on Promoting the Development of New Energy Storage", and if this goal is achieved, the new energy storage will reach at least 10 times more growth. At the same time, on June 6, 2022, the National Development and Reform Commission and the National Energy Administration jointly issued the Notice on Further Promoting the Participation of New Energy Storage in the Electricity Market and Dispatching (hereinafter referred to as the "Notice"), which clarifies many key issues such as identity, electricity price, trading mechanism, dispatching and operation mechanism of new energy storage in the participating market, which will have a far-reaching impact on the development of new energy storage in China during the "14th Five-Year Plan" period. With the continuous improvement of the market mechanism and the continuous development and maturity of technology, new energy storage will surely be able to shoulder the great task of achieving the "dual carbon" goal, and China will become the largest market leading the development of global energy storage. In 2025, the global installed capacity of energy storage is expected to reach 362GWh. As a key system to ensure the continuous and safe operation of energy storage systems, thermal management is expected to reach 14.1 billion yuan in 2025. At present, the value of a single system of liquid cooling in energy storage thermal management is higher than that of air cooling system, and there are mature solutions on the market, which is expected to become the mainstream temperature control scheme of energy storage thermal management in the future.

Gasgoo not only offers timely news and profound insight about China auto industry, but also help with business connection and expansion for suppliers and purchasers via multiple channels and methods. Buyer service:buyer-support@gasgoo.comSeller Service:seller-support@gasgoo.com